Fertilizer production equipment for pig manure

Fertilizer production equipment for pig manure typically includes the following processes and equipment:

1.Collection and storage: Pig manure is collected and stored in a designated area.

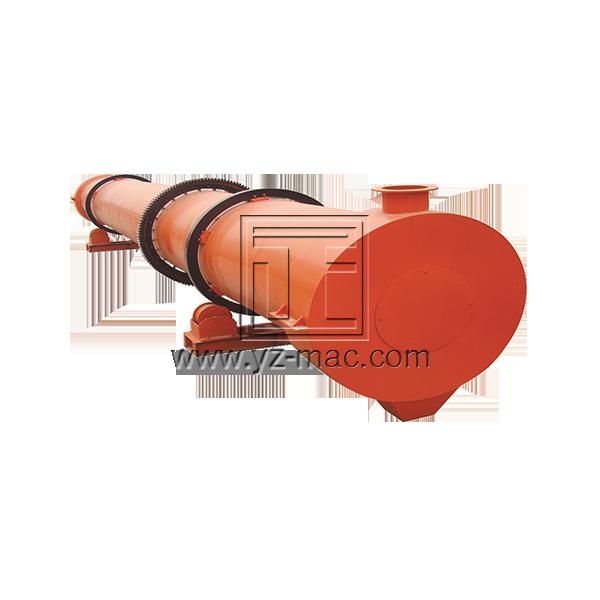

2.Drying: Pig manure is dried to reduce moisture content and eliminate pathogens. Drying equipment can include a rotary dryer or a drum dryer.

3.Crushing: Dried pig manure is crushed to reduce particle size for further processing. Crushing equipment can include a crusher or a hammer mill.

4.Mixing: Various additives, such as nitrogen, phosphorus, and potassium, are added to the crushed pig manure to create a balanced fertilizer. Mixing equipment can include a horizontal mixer or a vertical mixer.

5.Granulation: The mixture is then formed into granules for ease of handling and application. Granulation equipment can include a disc granulator, a rotary drum granulator, or a pan granulator.

6.Drying and cooling: The newly formed granules are then dried and cooled to harden them and prevent clumping. Drying and cooling equipment can include a rotary drum dryer and a rotary drum cooler.

7.Screening: The finished fertilizer is screened to remove any oversized or undersized particles. Screening equipment can include a rotary screener or a vibrating screener.

8.Coating: A coating can be applied to the granules to control nutrient release and improve their appearance. Coating equipment can include a rotary coating machine.

9.Packaging: The final step is to package the finished fertilizer into bags or other containers for distribution and sale. Packaging equipment can include a bagging machine or a weighing and filling machine.