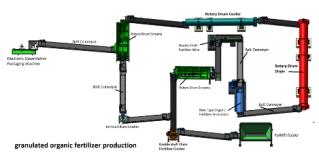

Fertilizer granulation process

Send email to us

Previous:

Fertilizer granulators

Next:

Fertilizer granule machine

The fertilizer granulation process is the core part of the organic fertilizer production line. The granulator achieves high-quality and uniform granulation through the continuous process of stirring, collision, inlay, spheroidization, granulation, and densification.

The uniformly stirred raw materials are fed into the fertilizer granulator, and granules of various desired shapes are extruded under the extrusion of the granulator die. The organic fertilizer granules after extrusion granulation have moderate hardness and neat shape.

Write your message here and send it to us