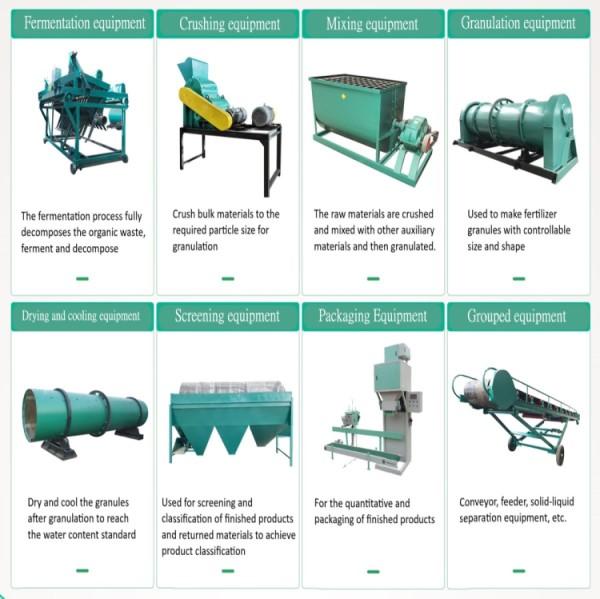

Fertilizer crushing equipment

Fertilizer crushing equipment is used to break down solid fertilizer materials into smaller particles, which can then be used to create different types of fertilizers. The size of the particles produced by the crusher can be adjusted, which allows for greater control over the final product.

There are several types of fertilizer crushing equipment available, including:

1.Cage Crusher: This equipment uses a cage with fixed and rotating blades to crush fertilizer materials. The rotating blades impact the material against the fixed blades, breaking it down into smaller pieces.

2.Half-wet Material Crusher: This type of equipment is used to crush materials that are damp or contain some moisture. It uses high-speed rotating blades to grind and crush the materials.

3.Chain Crusher: This type of equipment uses a chain with blades to crush the materials. The chain rotates at a high speed, breaking the materials into smaller pieces.

4.Vertical Crusher: This type of equipment is used to crush materials by impacting them against a hard surface. The materials are fed into a hopper and then dropped onto a spinning rotor, which crushes them into smaller particles.

5.Hammer Crusher: This equipment uses high-speed rotating hammers to crush and grind the materials. The hammers impact the materials, breaking them down into smaller pieces.

Fertilizer crushing equipment is commonly used in organic fertilizer production, as well as in the production of compound fertilizers. It can also be used to crush other materials, such as animal feed, grains, and chemicals. The choice of equipment depends on the type of material being crushed, as well as the desired particle size and production capacity.