Fertilizer blending equipment

Fertilizer blending equipment is an essential tool in the agricultural industry, enabling the precise and efficient mixing of various fertilizer components to create customized nutrient formulations.

Importance of Fertilizer Blending Equipment:

Customized Nutrient Formulations: Different crops and soil conditions require specific nutrient combinations. Fertilizer blending equipment allows for precise control over nutrient ratios, enabling the creation of customized fertilizer blends tailored to meet the specific needs of crops. This promotes optimal plant growth, productivity, and nutrient utilization.

Nutrient Management Efficiency: Fertilizer blending equipment ensures accurate and efficient mixing of various fertilizer components, such as nitrogen, phosphorus, potassium, and micronutrients. By creating homogeneous fertilizer blends, it facilitates uniform nutrient distribution in the field, reducing nutrient wastage and minimizing the risk of nutrient deficiencies or excesses.

Cost-Effectiveness: By blending different fertilizer components on-site, farmers and fertilizer manufacturers can save costs compared to purchasing pre-mixed fertilizers. Fertilizer blending equipment allows for flexibility in adjusting nutrient formulations based on crop requirements, soil analyses, and budget considerations.

Working Principle of Fertilizer Blending Equipment:

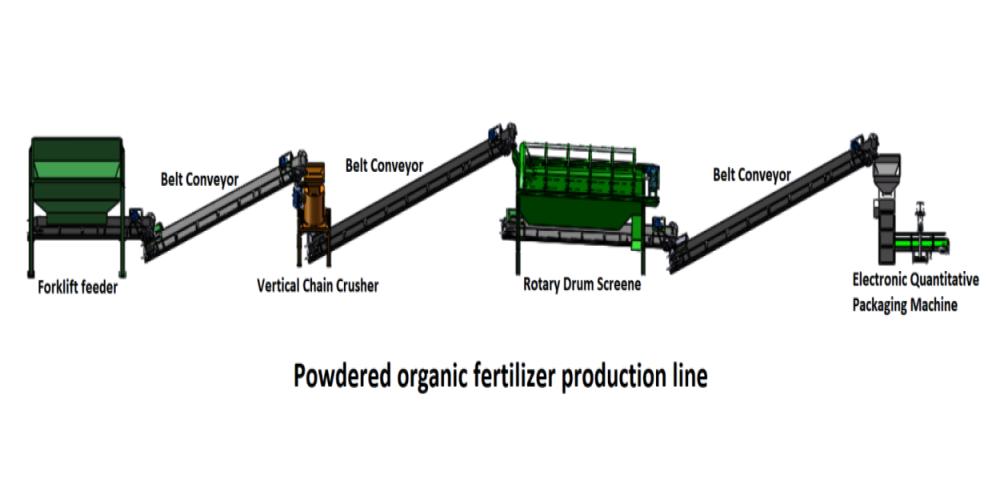

Fertilizer blending equipment operates on the principle of accurately metering and combining different fertilizer components to achieve the desired nutrient ratios. It typically consists of several hoppers or bins that hold individual fertilizer components. These components are precisely measured and discharged into a mixing chamber or blender, where they are thoroughly mixed to create a homogeneous blend. The blended fertilizer is then collected and stored for application.

Applications of Fertilizer Blending Equipment:

Agricultural Production: Fertilizer blending equipment is widely used in agricultural production systems, including large-scale farms and commercial fertilizer manufacturing plants. It enables the creation of customized fertilizer formulations tailored to specific crop nutrient requirements, soil conditions, and regional factors.

Soil Amendment and Nutrient Management: Fertilizer blending equipment is employed in soil amendment programs aimed at improving soil fertility and nutrient management. It allows for the incorporation of organic amendments, such as compost, manure, or biofertilizers, into the fertilizer blend, enhancing soil health and nutrient availability.

Specialty Crop Production: Fertilizer blending equipment is particularly valuable in specialty crop production, where precise nutrient management is crucial. It enables farmers to create fertilizer blends that cater to the unique nutritional needs of specialty crops, ensuring optimal yield and quality.

Customized Fertilizer Manufacturing: Fertilizer blending equipment is used by fertilizer manufacturers to produce customized fertilizer products for specific crop types or regional demands. It enables the production of tailored fertilizers that meet the requirements of different agricultural sectors and niche markets.

Fertilizer blending equipment plays a vital role in agricultural nutrient management by allowing the creation of customized fertilizer blends tailored to specific crop and soil needs. By ensuring accurate nutrient ratios and efficient mixing, this equipment optimizes plant nutrition, improves crop productivity, and reduces nutrient wastage. Fertilizer blending equipment finds applications in agricultural production, soil amendment programs, specialty crop production, and customized fertilizer manufacturing.