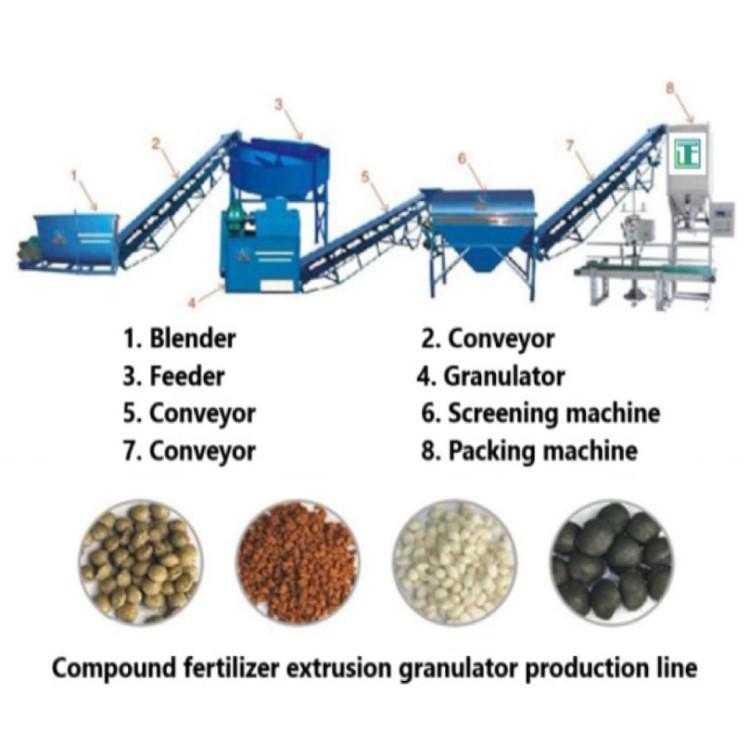

Fertilizer belt conveyor

A fertilizer belt conveyor is a type of industrial equipment that is used to transport fertilizers and other materials from one location to another within a production or processing facility. The conveyor belt is typically made of a rubber or plastic material and is supported by rollers or other supporting structures.

Fertilizer belt conveyors are commonly used in the fertilizer manufacturing industry to transport raw materials, finished products, and waste materials between different stages of the production process. The conveyors can be designed to operate at different speeds and can be configured to transport materials in a variety of directions, including up and down, as well as horizontally.

One of the advantages of using a fertilizer belt conveyor is that it can help to improve efficiency and productivity within a production facility. By automating the process of transporting materials, the conveyor can help to reduce labor costs and increase the speed and accuracy of material handling. Additionally, the conveyor can be designed to operate continuously, which can help to maximize production output.

However, there are also some potential drawbacks to using a fertilizer belt conveyor. For example, the conveyor may require frequent maintenance and cleaning to ensure that it is operating efficiently and effectively. Additionally, the conveyor may generate noise, dust, or other emissions, which can be a safety hazard or environmental concern. Finally, the conveyor may require a significant amount of energy to operate, which can result in higher energy costs.