Duck manure fertilizer screening equipment

Duck manure fertilizer screening equipment refers to machines that are used to separate solid particles from liquid or to classify the solid particles according to their size. These machines are typically used in the fertilizer production process to remove impurities or oversized particles from duck manure fertilizer.

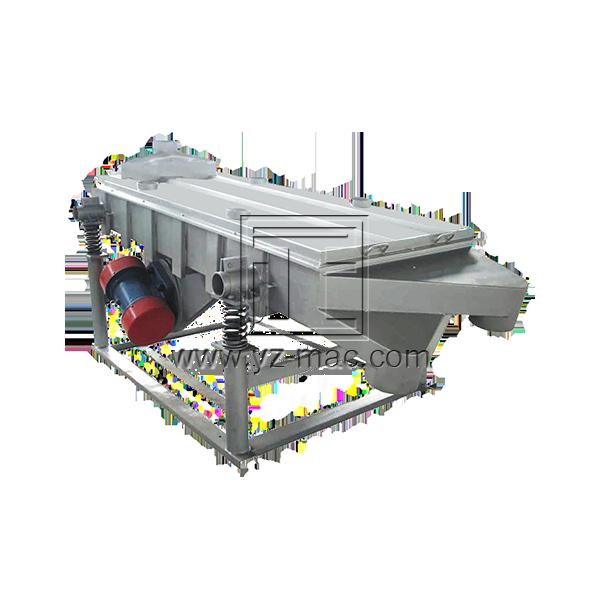

There are several types of screening equipment that can be used for this purpose, including vibrating screens, rotary screens, and drum screens. Vibrating screens use a vibration motor to generate a three-dimensional vibration, which causes the material to be thrown up and moved forward in a straight line on the screen surface. Rotary screens use a rotating drum to separate the material based on size, while drum screens use a rotating cylindrical drum to separate material.

The choice of screening equipment will depend on the specific requirements of the duck manure fertilizer production process, such as the required capacity, the particle size distribution of the fertilizer, and the desired level of automation.