Dry granulator

A dry granulator, also known as a dry granulation machine, is a specialized equipment designed for the granulation of dry materials without the need for liquid binders or solvents. This process involves compacting and shaping dry powders or particles into granules, which are easier to handle, store, and transport. In this article, we will explore the benefits, working principle, and applications of dry granulators in various industries.

Benefits of Dry Granulation:

No Liquid Binders or Solvents: Dry granulation eliminates the need for liquid binders or solvents commonly used in wet granulation processes. This reduces the complexity of the granulation process, simplifies handling and cleanup, and eliminates the risk of cross-contamination or environmental concerns associated with liquid-based binders.

Improved Stability: Dry granules have enhanced stability compared to powders or loose particles. The compacted nature of granules minimizes segregation, prevents moisture absorption, and enhances flow properties. This stability ensures consistent product quality and reduces the risk of degradation during storage or transportation.

Cost Savings: Dry granulation offers cost advantages by eliminating the need for liquid binders, drying processes, and associated equipment. It reduces energy consumption, production time, and maintenance requirements, resulting in cost savings for manufacturers.

Customizable Granule Properties: Dry granulation allows for precise control over the granule properties, such as size, shape, density, and porosity. This enables manufacturers to tailor the granules to specific application requirements, ensuring optimal performance and desired product characteristics.

Working Principle of Dry Granulators:

Dry granulators typically employ two main processes: compaction and milling.

Compaction: In the compaction stage, dry powders or particles are fed into a granulation chamber, where a pair of counter-rotating rolls or a mechanical press applies pressure to compact the material. The compacted material undergoes plastic deformation, forming a ribbon or sheet.

Milling: The compacted ribbon or sheet is then passed through a milling system, which consists of a set of knives or blades that break the material into granules of the desired size. The milled granules are collected and can undergo additional processing steps, such as sieving or coating, if necessary.

Applications of Dry Granulators:

Pharmaceutical Industry: Dry granulation is widely used in pharmaceutical manufacturing for the production of tablets, capsules, and other solid dosage forms. It enables the direct compression of drug powders into granules, improving flowability, uniformity, and tabletability. Dry granulators are suitable for both small-scale and large-scale pharmaceutical production.

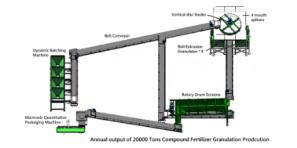

Chemical Industry: Dry granulation is employed in the chemical industry for the production of granular fertilizers, catalysts, pigments, and other chemical products. The process enables precise control over granule properties, such as size, density, and porosity, ensuring consistent product quality and improved handling characteristics.

Food and Nutraceutical Industry: Dry granulation is used in the food and nutraceutical industries to produce granular ingredients, dietary supplements, and food additives. It allows for the formulation of custom blends, controlled release systems, and improved flowability for efficient processing and consumer convenience.

Powder Metallurgy: Dry granulation plays a significant role in powder metallurgy, where metal powders are compacted and granulated to form feedstocks for subsequent processes like compaction, sintering, and shaping. Dry granulation enhances the flow properties, density, and uniformity of metal powders, facilitating their handling and subsequent manufacturing operations.

Conclusion:

Dry granulators offer efficient and cost-effective granulation of dry materials without the need for liquid binders or solvents. With benefits such as improved stability, cost savings, and customizable granule properties, dry granulation has found applications in various industries, including pharmaceuticals, chemicals, food, nutraceuticals, and powder metallurgy. By utilizing dry granulators, manufacturers can achieve consistent product quality, enhance handling characteristics, and optimize their manufacturing processes.