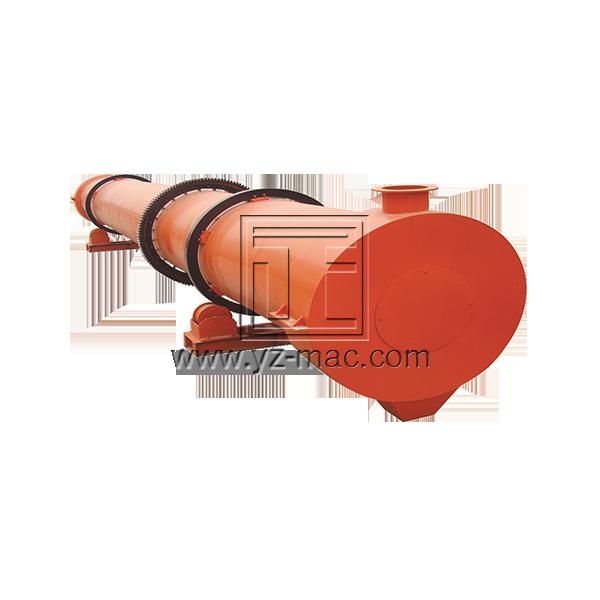

Dry granulation equipment

Dry granulation equipment is a specialized machinery used to transform powder materials into granules without the need for liquid binders or additives. This process involves compacting and densifying the powder particles, resulting in granules that are uniform in size, shape, and density.

Benefits of Dry Granulation Equipment:

Powder Handling Efficiency: Dry granulation equipment allows for efficient handling of powders, minimizing dust generation and improving the overall working environment. The equipment ensures better containment of the powder during the granulation process, reducing material loss and maintaining a clean production area.

No Liquid Binders Required: Unlike wet granulation methods that rely on liquid binders, dry granulation eliminates the need for additives, simplifying the granulation process and reducing the overall production costs. It offers a more environmentally friendly approach as it eliminates the use of water or organic solvents.

Improved Flowability and Dispersion: Dry granulation improves the flow properties of powders by increasing their particle size and density. Granules produced by the equipment have enhanced flowability, ensuring consistent and uniform material distribution during subsequent processing steps, such as blending, filling, and packaging.

Controlled Granule Characteristics: Dry granulation equipment provides precise control over the size, shape, and density of the granules. By adjusting the compaction force and utilizing different tooling options, manufacturers can tailor the granule properties to meet specific product requirements, ensuring uniformity and optimizing product performance.

Working Principle of Dry Granulation Equipment:

Dry granulation typically involves two main processes: compaction and milling.

Compaction: In this stage, the powder material is fed into the equipment, and high pressure is applied to compact the powder particles. The compaction force causes the particles to adhere and form densified granules.

Milling: The compacted granules are then passed through a milling or size reduction process to break them down into the desired granule size range. This step ensures uniformity and eliminates any oversized granules.

Applications of Dry Granulation Equipment:

Pharmaceutical Industry: Dry granulation equipment is extensively used in the pharmaceutical industry for tablet manufacturing. It produces granules that can be directly compressed into tablets, eliminating the need for wet granulation and drying steps. This process ensures uniform drug content, enhanced dissolution properties, and improved tablet integrity.

Chemical Industry: Dry granulation equipment finds applications in the chemical industry for the production of granular materials used in various formulations, such as fertilizers, catalysts, detergents, and pigments. The controlled granule characteristics achieved through dry granulation enable consistent product quality and facilitate downstream processing.

Food and Nutraceutical Industry: Dry granulation is employed in the food and nutraceutical industry for the production of granulated ingredients, additives, and dietary supplements. It helps improve flowability, prevent ingredient segregation, and facilitate accurate dosing in food processing and supplement manufacturing.

Material Recycling: Dry granulation equipment is utilized in recycling processes to transform powdered materials, such as plastic particles or metal powders, into granules. These granules can be further processed and reused, reducing waste and promoting a more sustainable approach to material recycling.

Dry granulation equipment offers numerous benefits in terms of powder handling efficiency, elimination of liquid binders, improved flowability, and controlled granule characteristics. The working principle of dry granulation involves compaction and milling processes, resulting in uniform and well-defined granules. This equipment finds applications in industries such as pharmaceuticals, chemicals, food, nutraceuticals, and material recycling, where granule production is critical.