Drum fertilizer granulation equipment

Drum fertilizer granulation equipment, also known as rotary drum granulator, is a type of granulator commonly used in the production of fertilizers. It is particularly suitable for processing materials such as animal manure, crop residues, and other organic waste products into granules.

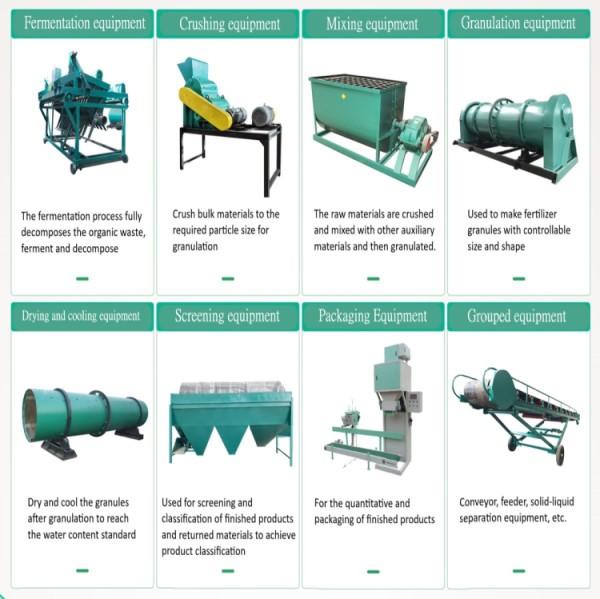

The equipment consists of a rotating drum with an inclined angle, a feeding device, a granulating device, a discharging device, and a supporting device. The raw materials are fed into the drum through the feeding device, and as the drum rotates, they are tumbled and mixed together. The granulating device sprays a liquid binder onto the materials, causing them to form into granules. The granules are then discharged from the drum and transported to a drying and cooling system.

The advantages of using drum fertilizer granulation equipment include:

1.High Granulation Rate: The tumbling action of the drum and the use of a liquid binder result in a high granulation rate and uniform particle size.

2.Wide Range of Raw Materials: The equipment can be used to process a variety of organic and inorganic materials, making it a versatile option for fertilizer production.

3.Energy Efficient: The drum rotates at a low speed, requiring less energy than other types of granulators.

4.Easy Maintenance: The equipment is simple in design and easy to operate and maintain.

Drum fertilizer granulation equipment is a useful tool in the production of high-quality, efficient fertilizers that can help improve soil health and crop yields.