Disc granulator machine

A disc granulator machine is a specialized equipment used in fertilizer production to convert various materials into granules. It plays a crucial role in the granulation process, transforming raw materials into uniform-sized particles suitable for fertilizer application.

Key Features of a Disc Granulator Machine:

Disc Design: A disc granulator machine features a rotating disc that facilitates the granulation process. The disc is often inclined, allowing materials to be evenly distributed and granulated as it rotates. The disc’s design ensures efficient and consistent granule formation.

Adjustable Angle and Speed: Disc granulators offer flexibility with adjustable angles and rotation speeds. The angle and speed can be optimized to achieve the desired granule size and quality, accommodating different fertilizer formulations and production requirements.

Wet Granulation Process: Disc granulation employs a wet granulation process, where the raw materials are mixed with a binder or liquid solution to form granules. The wet granulation process helps enhance particle cohesion, resulting in well-formed and durable fertilizer granules.

Continuous Operation: Disc granulator machines are designed for continuous operation, allowing for high production rates and improved efficiency. The continuous process ensures a consistent output of granules, making it suitable for large-scale fertilizer production.

Working Principle of a Disc Granulator Machine:

The working principle of a disc granulator machine involves several stages:

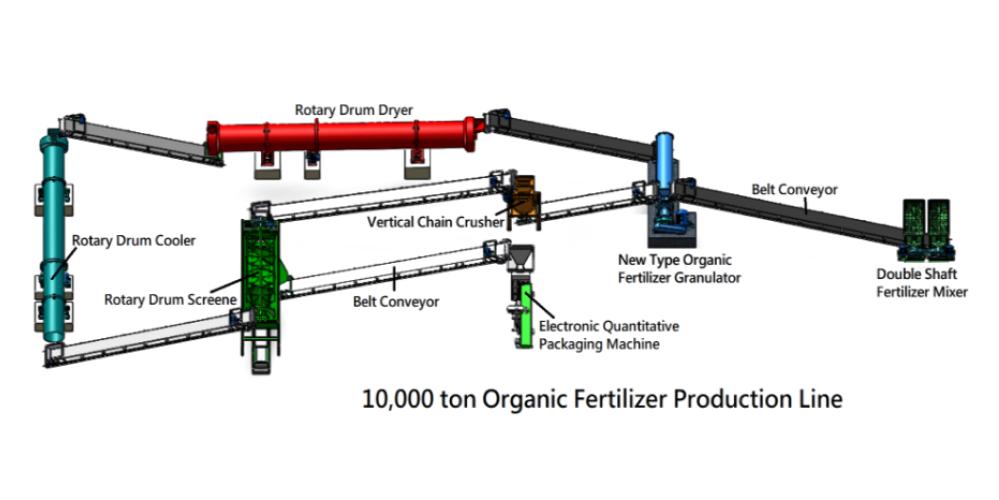

Material Pre-processing: Raw materials, such as powdered or small-sized substances, are typically pre-processed to ensure a uniform size and moisture content. This may involve crushing, grinding, or drying, depending on the specific materials used.

Mixing and Conditioning: The pre-processed materials are mixed with binders or liquid solutions to improve their adhesive properties and granule formation. This step helps create a homogeneous mixture for granulation.

Granulation: The mixture is then fed onto the rotating disc of the granulator machine. The centrifugal force generated by the rotating disc causes the material to form into spherical granules. As the granules grow, they gain strength and size through collision and layering.

Drying and Cooling: After granulation, the newly formed granules may undergo a drying and cooling process to remove excess moisture and ensure stable storage and handling.

Applications of Disc Granulator Machines:

Agricultural Fertilizers: Disc granulator machines are widely used in the production of agricultural fertilizers. They can convert a variety of materials, including nitrogen-based compounds, phosphorus, and potassium sources, into granules suitable for crop nutrition and soil enrichment.

Organic Fertilizers: Disc granulators are effective in granulating organic materials, such as animal manure, crop residues, and compost. The granulated organic fertilizers provide a slow-release nutrient source, improving soil fertility and promoting sustainable agricultural practices.

Compound Fertilizers: Disc granulator machines are also utilized in the production of compound fertilizers. By combining multiple nutrient sources and additives, such as nitrogen, phosphorus, and potassium, in specific ratios, compound fertilizers can be granulated to provide balanced nutrition for various crops.

Specialty Fertilizers: Disc granulators are versatile and can be used for the production of specialty fertilizers tailored to specific crop needs or soil conditions. This includes micronutrient-enriched fertilizers, controlled-release fertilizers, and custom formulations for specialized crops.

A disc granulator machine is an essential tool in efficient fertilizer production. Its features, such as a rotating disc, adjustable angle and speed, and continuous operation, ensure uniform and high-quality granules suitable for various fertilizers. Disc granulators utilize a wet granulation process, allowing for excellent particle cohesion and durability. With applications in agricultural fertilizers, organic fertilizers, compound fertilizers, and specialty fertilizers, disc granulator machines contribute to sustainable agriculture and soil enrichment. Investing in a disc granulator machine enables efficient fertilizer production, promoting enhanced crop productivity and environmental stewardship.