Buffer granulation equipment

Buffer granulation equipment is used to create buffer or slow-release fertilizers. These types of fertilizers are designed to release nutrients slowly over an extended period of time, reducing the risk of over-fertilization and nutrient leaching. Buffer granulation equipment uses a variety of techniques to create these types of fertilizers, including:

1.Coating: This involves coating the fertilizer granules with a material that slows down the release of nutrients. The coating material can be a polymer, wax, or other substance.

2.Encapsulation: This involves enclosing the fertilizer granules in a capsule made of a slow-release material, such as a polymer or resin. The capsule gradually dissolves, releasing the fertilizer over time.

3.Blending: This involves blending different types of fertilizers with different release rates to create a slow-release or buffer fertilizer.

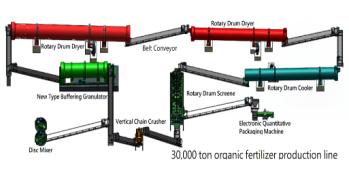

Buffer granulation equipment can use various methods to achieve these techniques, such as fluidized bed granulation, spray granulation, or drum granulation. The specific equipment used will depend on the desired method and the type of fertilizer being produced.

Buffer granulation equipment offers several benefits, including:

1.Reduced fertilizer application frequency: Buffer fertilizers can release nutrients slowly over an extended period of time, reducing the need for frequent fertilizer applications.

2.Reduced nutrient losses: Slow-release or buffer fertilizers can help reduce nutrient leaching and runoff, improving the efficiency of fertilizer use and reducing environmental pollution.

3.Improved plant growth: Buffer fertilizers can provide a steady supply of nutrients to plants, promoting healthy growth and reducing the risk of nutrient deficiencies.

Buffer granulation equipment plays an important role in the production of slow-release and buffer fertilizers, which can provide numerous benefits for both farmers and the environment.