Bio organic fertilizer production line

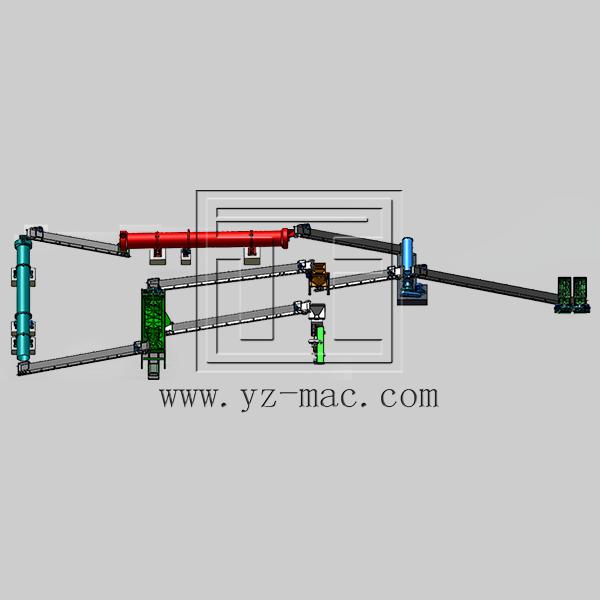

Bio-organic fertilizer production line is a type of organic fertilizer production line that uses specific microorganisms and fermentation technology to process organic waste materials into high-quality bio-organic fertilizers. The production line typically includes several key machines, such as a compost turner, crusher, mixer, granulator, dryer, cooler, screening machine, and packaging machine.

The production process of bio-organic fertilizer involves the following steps:

Preparation of raw materials: This involves collecting organic waste materials such as crop straw, livestock and poultry manure, kitchen waste, and other organic wastes.

Fermentation: The raw materials are then placed in a fermentation tank and specific microorganisms are added to aid in the decomposition and conversion of the organic materials into bio-organic fertilizer.

Crushing and mixing: The fermented materials are then crushed and mixed to create a uniform and homogeneous mixture.

Granulation: The mixed materials are then processed into granules using a bio-organic fertilizer granulator.

Drying: The granulated bio-organic fertilizer is then dried using a bio-organic fertilizer dryer.

Cooling: The dried fertilizer is cooled to room temperature using a bio-organic fertilizer cooler.

Screening: The cooled fertilizer is screened to remove any oversized or undersized granules.

Packaging: The final step involves packaging the bio-organic fertilizer into bags for distribution and sale.

Overall, bio-organic fertilizer production lines are a sustainable and eco-friendly way of processing organic waste materials into high-quality fertilizers that can be used to improve soil health and crop yields.