Best compost turner

Determining the best compost turner depends on various factors, including the scale of operations, composting goals, available space, and specific requirements. Here are a few types of compost turners that are commonly considered among the best in their respective categories:

Tow-Behind Compost Turners:

Tow-behind compost turners are versatile machines that can be attached to a tractor or other suitable vehicles. They are suitable for medium to large-scale composting operations, such as farms or municipalities. These turners typically feature rotating drums or augers that lift and mix the compost pile, ensuring effective aeration and thorough mixing.

Self-Propelled Compost Turners:

Self-propelled compost turners are standalone machines equipped with their own engines or power systems. They are designed for larger-scale composting operations, including commercial composting facilities or composting operations that handle significant volumes of organic waste. These turners offer high maneuverability and flexibility, allowing operators to efficiently turn and mix large compost piles.

Windrow Compost Turners:

Windrow compost turners are specifically designed for composting in windrow configurations. They are ideal for medium to large-scale operations, such as municipal composting facilities or agricultural composting operations. These turners can handle long, narrow piles of compost and feature rotating drums, augers, or paddles to lift and mix the material for optimal aeration and decomposition.

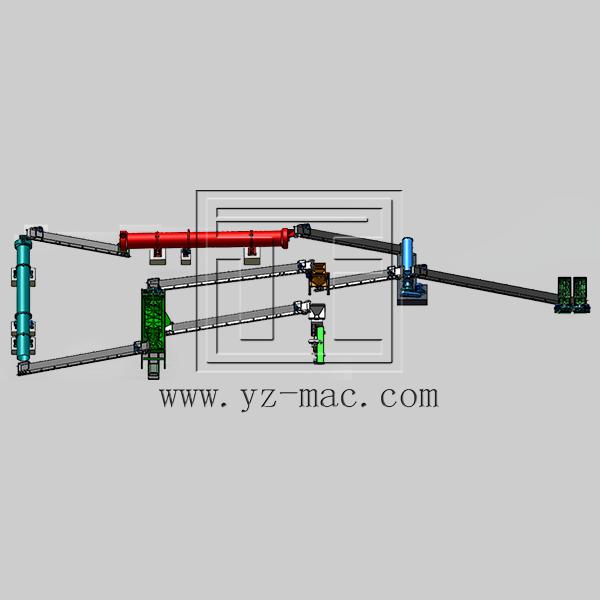

In-Vessel Compost Turners:

In-vessel compost turners are designed for composting within enclosed systems, such as in-vessel composting facilities. These turners provide precise control over temperature, moisture, and aeration within the vessel, resulting in efficient decomposition. They are suitable for large-scale commercial or industrial composting operations that require high levels of control and automation.

When selecting the best compost turner, consider factors such as the scale of composting operations, available space, desired automation level, and budget.