batch dryer

A continuous dryer is a type of industrial dryer that is designed to process materials continuously, without the need for manual intervention between cycles. These dryers are typically used for high-volume production applications where a steady supply of dried material is required.

Continuous dryers can take several forms, including conveyor belt dryers, rotary dryers, and fluidized bed dryers. The choice of dryer depends on factors such as the type of material being dried, the desired moisture content, the production capacity, and the required drying time.

Conveyor belt dryers use a continuous conveyor belt to move material through a heated drying chamber. As the material moves through the chamber, hot air is blown over it to remove moisture.

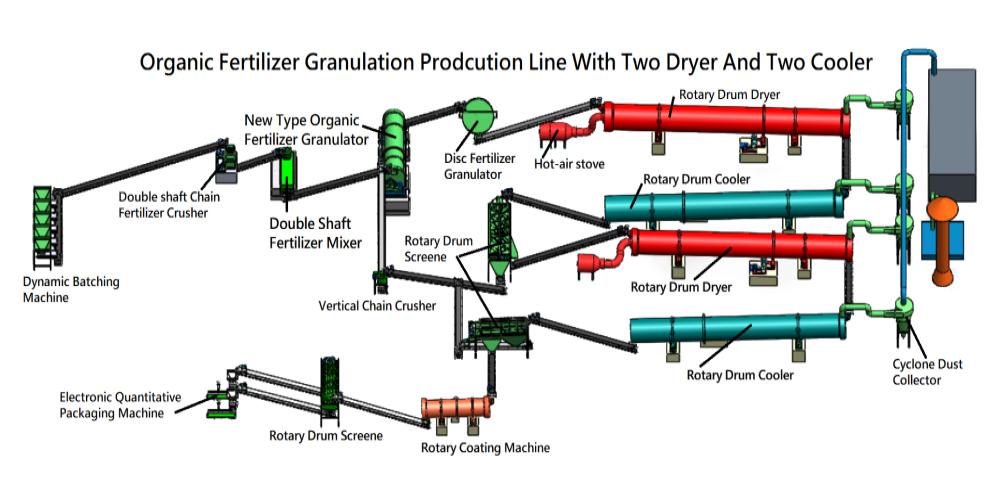

Rotary dryers consist of a large, rotating drum that is heated with a direct or indirect burner. Material is fed into the drum at one end and moves through the dryer as it rotates, coming into contact with the heated walls of the drum and the hot air flowing through it.

Fluidized bed dryers use a bed of hot air or gas to suspend and transport material through a drying chamber. The material is fluidized by the hot gas, which removes moisture and dries the material as it moves through the dryer.

Continuous dryers offer several advantages over batch dryers, including higher production rates, lower labor costs, and greater control over the drying process. However, they can also be more expensive to operate and maintain, and may require more energy to run than batch dryers.