Wholesale Price China Pellets Screener - Linear Vibrating Screener – YiZheng

Wholesale Price China Pellets Screener - Linear Vibrating Screener – YiZheng Detail:

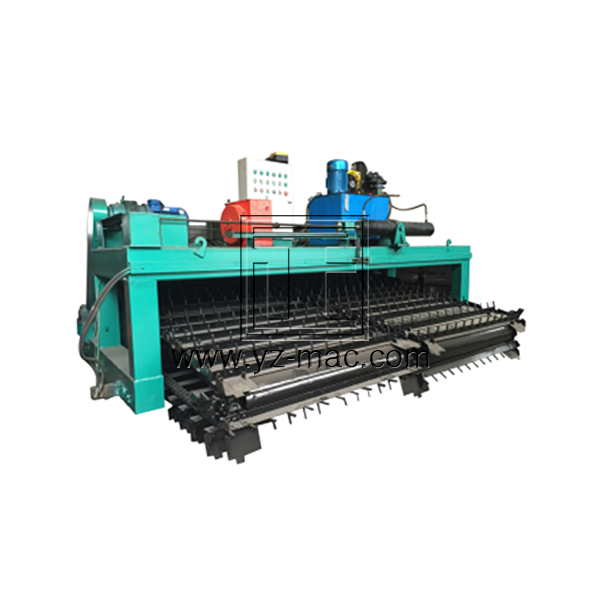

The Linear Vibrating Screener (Linear Vibrating Screen) uses vibration motor excitation as the vibration source to make the material shake up on the screen and moves forward in a straight line. The material enters the feeding port of the screening machine evenly from the feeder. Several sizes of oversize and undersize are produced by a multi-layer screen and are discharged from respective outlets.

When the linear screen is working, the synchronous rotation of the two motors causes the vibration exciter to generate a reverse excitation force, forcing the screen body to move the screen longitudinally, so that the material on the material is excited and periodically throws a range. Thereby completing the material screening operation. The linear vibrating screen is driven by a double-vibration motor. When the two vibrating motors are synchronously and reversely rotated, the exciting force generated by the eccentric block cancels each other in the lateral direction, and the combined excitation force in the longitudinal direction is transmitted to the entire screen. On the surface, therefore, the movement path of the sieve machine is a straight line. The direction of the exciting force has an inclination angle with respect to the screen surface. Under the combined action of the exciting force and the self-gravity of the material, the material is thrown up and jumped forward in a linear motion on the screen surface, thereby achieving the purpose of screening and classifying the material.

1. Good sealing and very little dust.

2. Low energy consumption, low noise and long service life of the screen.

3. High screening precision, large processing capacity and simple structure.

4. Fully enclosed structure, automatic discharge, more suitable for assembly line operations.

5. All parts of the screen body are welded by steel plate and profile (the bolts are connected between some groups). The overall rigidity is good, firm and reliable.

|

Model |

Screen Size (mm) |

Length (mm) |

Power (kW) |

Capacity (t/h) |

Speed (r/min) |

|

BM1000 |

1000 |

6000 |

5.5 |

3 |

15 |

|

BM1200 |

1200 |

6000 |

7.5 |

5 |

14 |

|

BM1500 |

1500 |

6000 |

11 |

12 |

12 |

|

BM1800 |

1800 |

8000 |

15 |

25 |

12 |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Compound fertilizer production process

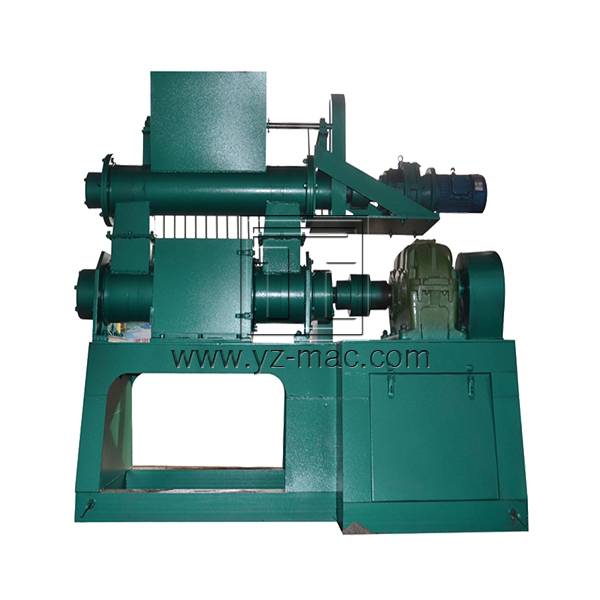

Moisture Control - During the manure composting process, the relative moisture content of the composting raw material is 40% to 70%, which ensures the smooth progress of composting. Wholesale Price China Pellets Screener - Linear Vibrating Screener – YiZheng , The product will supply to all over the world, such as: Sydney, Portland, Switzerland, The raw material after cow dung fermentation enters the pulverizer to pulverize the bulk material into small pieces that can meet the granulation requirements. Then the material is sent to the mixer equipment by the belt conveyor, mixed with other auxiliary materials evenly and then enters the granulation process.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!