Small pig manure organic fertilizer production equipment

Small-scale pig manure organic fertilizer production equipment typically includes the following machines and equipment:

1.Shredding equipment: Used to shred the pig manure into small pieces. This includes shredders and crushers.

2.Mixing equipment: Used to mix the shredded pig manure with other additives, such as microorganisms and minerals, to create a balanced fertilizer blend. This includes mixers and blenders.

3.Fermentation equipment: Used to ferment the mixed material, which helps to break down the organic matter and convert it into a more stable, nutrient-rich fertilizer. This includes fermentation tanks and compost turners.

4.Crushing and screening equipment: Used to crush and screen the fermented material to create a uniform size and quality of the final product. This includes crushers and screening machines.

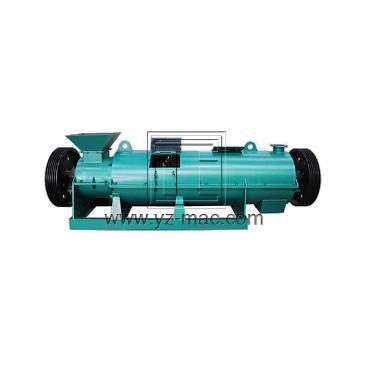

5.Granulating equipment: Used to convert the screened material into granules or pellets. This includes pan granulators, rotary drum granulators, and disc granulators.

6.Drying equipment: Used to reduce the moisture content of the granules, making them easier to handle and store. This includes rotary dryers, fluidized bed dryers, and belt dryers.

7.Cooling equipment: Used to cool the granules after drying to prevent them from sticking together or breaking down. This includes rotary coolers, fluidized bed coolers, and counter-flow coolers.

8.Coating equipment: Used to add a coating to the granules, which can improve their resistance to moisture and improve their ability to release nutrients over time. This includes rotary coating machines and drum coating machines.

9.Screening equipment: Used to remove any oversized or undersized granules from the final product, ensuring that the product is of consistent size and quality. This includes vibrating screens and rotary screens.

10.Packing equipment: Used to package the final product into bags or containers for storage and distribution. This includes automatic bagging machines, filling machines, and palletizers.

Small-scale pig manure organic fertilizer production equipment is designed to produce organic fertilizers from pig manure on a small scale, typically for use in home gardens or small farms. The equipment can be customized to suit different production capacities and requirements, depending on the specific needs of the user. Small-scale equipment may be manually operated or semi-automatic, and may require less power and labor than larger-scale equipment. This makes it an affordable and accessible option for farmers and gardeners who want to produce their own organic fertilizers using pig manure as a raw material.