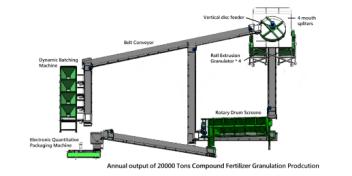

Sheep manure fertilizer granulation equipment

Sheep manure can also be processed into fertilizer using granulation equipment. The process of granulation involves mixing the sheep manure with other ingredients and then shaping the mixture into small pellets or granules that are easier to handle, store, and transport.

There are several types of granulation equipment that can be used for sheep manure fertilizer production, including:

1.Rotary drum granulator: This is a popular option for producing large quantities of sheep manure fertilizer pellets. The process involves adding a binder to the sheep manure and other ingredients and then tumbling the mixture in a rotating drum. The heat generated by the drum helps to solidify the mixture into pellets.

2.Disc granulator: This type of granulator uses a rotating disc to agglomerate the sheep manure and other materials into pellets. The disc has a series of angled blades that help to mix the ingredients and shape them into round pellets.

3.Pan granulator: Similar to the disc granulator, the pan granulator uses a rotating pan to agglomerate the sheep manure and other materials into pellets. The pan has a series of angled blades that help to mix the ingredients and shape them into round pellets.

4.Extrusion granulator: This type of granulator uses a screw extruder to force the sheep manure and other materials through a die to create pellets. The extruder applies pressure to the mixture, which helps to shape it into pellets.

5.Roller press granulator: This type of granulator uses two rollers to compress the sheep manure and other materials into pellets. The pressure created by the rollers helps to shape the mixture into pellets.

After the sheep manure has been processed into pellets, it can be further treated with drying, cooling, coating, and other equipment to create a high-quality fertilizer product.