Reasonable price Animal Dung Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng

Reasonable price Animal Dung Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng Detail:

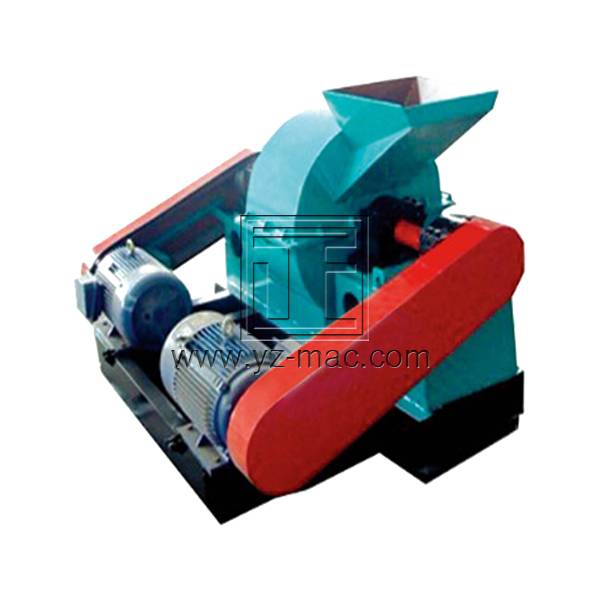

The Chemical Fertilizer Cage Mill Machine belongs to medium-sized horizontal cage mill. This machine is designed according to the principle of impact crushing. When the inside and outside cages rotate in opposite direction with high speed, the material is crushed from inside to outside by the impact of the cage. The cage crusher has the advantages of simple structure, high crushing efficiency, good sealing performance, stable operation, easy cleaning, convenient maintenance and so on.

The Chemical Fertilizer Cage Mill Machine is composed of frame, casing, rat wheel group, mouse wheel group and two electric motors. When working, a motor drives the large cage to rotate smoothly. The other motor drives the small cage to rotate reversely, and the material enters the inner mouse wheel frame through the hopper, the high speed rotating steel bar repeatedly impacts and breaks the material, so as to achieve the fine crushing effect.

(1) This is the one of horizontal cage mill for middle size.

(2) Especially suitable for materials with higher hardness

(3) It has a simple structure and high crushing efficiency

(4) Smooth operation, easy to clean, easy to maintain.

|

Model |

Power(KW) |

Speed (r/min) |

Capacity(t/h) |

Weight (kg) |

|

YZFSLS-600 |

11+15 |

1220 |

4-6 |

2300 |

|

YZFSLS-800 |

15+22 |

1220 |

6-10 |

2550 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Pig manure organic fertilizer complete equipment

- Both powders and granules can be screened out by trommel screening machine. Reasonable price Animal Dung Crusher - Chemical Fertilizer Cage Mill Machine – YiZheng , The product will supply to all over the world, such as: Southampton, Stuttgart, Rotterdam, The organic fertilizer granulator is used to granulate various organic substances after fermentation. Before granulation, there is no need to dry and pulverize the raw materials. The spherical granules can be processed directly with ingredients, which can save a lot of energy.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!