Professional China Dynamic Batching Machine - Organic Fertilizer Round Polishing Machine – YiZheng

Professional China Dynamic Batching Machine - Organic Fertilizer Round Polishing Machine – YiZheng Detail:

1.The bio-organic granulation fertilizer which makes peat, lignite, organic fertilizer sludge, straw as raw material

2.Organic granulation fertilizer which makes chicken manure as raw material

3.Cake fertilizer which makes soy-bean cake as raw material

4.Mixed feed which makes corn, beans, grass meal as raw material

5.Bio-feed which makes crop straw as raw material

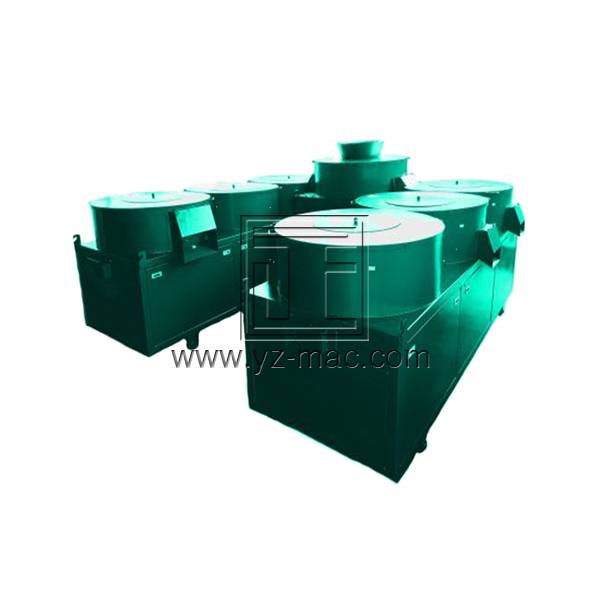

1. High output. It can be flexible worked with one or several granulators at the same time in the process, solving the disadvantage that a granulator must be equipped with a coating machine.

2. The machine is made up by two or more polishing cylinder orderly, the material will be out after several times polishing, the finished product has uniform size, consistent density and nice appearance, and the shaping rate is up to 95%.

3. It has simple structure, safe and reliable.

4. Easy operation and maintenance.

5. Strong adaptability, it can work in various environments.

6. Low power consumption, low production cost and high economic benefits.

|

Model |

YZPY-800 |

YZPY-1000 |

YZPY-1200 |

|

Power (KW) |

8 |

11 |

11 |

|

Disc Diameter (mm) |

800 |

1000 |

1200 |

|

Shape Size (mm) |

1700×850×1400 |

2100×1100×1400 |

2600×1300×1500 |

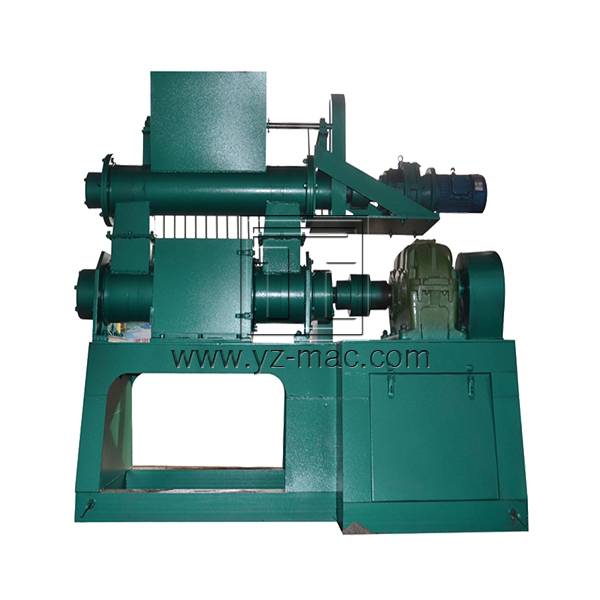

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Pig manure organic fertilizer complete equipment

Moisture Control - During the manure composting process, the relative moisture content of the composting raw material is 40% to 70%, which ensures the smooth progress of composting. Professional China Dynamic Batching Machine - Organic Fertilizer Round Polishing Machine – YiZheng , The product will supply to all over the world, such as: azerbaijan, UK, Doha, The organic fertilizer mixer is used for granulation after the raw materials are pulverized and mixed with other auxiliary materials evenly. During the churning process, mix the powdered compost with any desired ingredients or recipes to increase its nutritional value. The mixture is then granulated using a granulator.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!