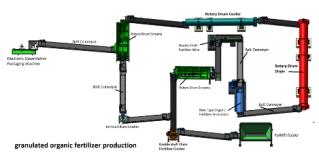

Organic fertilizer supporting equipment

Organic fertilizer supporting equipment refers to various equipment used in order to improve production efficiency and product quality in the process of organic fertilizer production. The types and functions of these equipment are various, involving multiple links in the organic fertilizer production process The following will briefly introduce several common organic fertilizer supporting equipment.

1. Organic fertilizer turning machine

Organic fertilizer turning machine is one of the essential equipment in the process of organic fertilizer production. Its main function is to turn and mix organic fertilizers so that they can fully contact the air and accelerate the decomposition of organic substances. At the same time, it can also control parameters such as temperature and humidity to ensure the quality of organic fertilizers.

2. Organic fertilizer mixer

The organic fertilizer mixer is mainly used to mix different kinds of organic fertilizers and additives in order to obtain a more uniform organic fertilizer product. At the same time, during the production process, the organic fertilizer mixer can also control the moisture content and mixing ratio to improve the quality of organic fertilizer.

3. Organic fertilizer grinder

The organic fertilizer pulverizer is mainly used to crush organic matter and additives for better mixing and granulation. The organic fertilizer pulverizer can crush different types of organic substances into particles of the same size, which is of great significance for the uniform mixing and pre-granulation of organic fertilizers.

4. Organic fertilizer granulator

The organic fertilizer granulator is mainly used for pressure molding of organic matter to obtain organic fertilizer granules of various shapes and sizes. The organic fertilizer granulator can effectively improve the quality and production efficiency of organic fertilizers, and at the same time reduce product loss and pollution.

5. Organic fertilizer dryer

The organic fertilizer dryer is a kind of equipment specially used for drying organic fertilizers. It can dry fresh organic fertilizers to prolong their shelf life and better store and transport them.

6. Organic fertilizer conveyor

The organic fertilizer conveyor is an important equipment in the organic fertilizer production line. Through automatic transportation, the organic fertilizer raw materials or finished products in the production line are transported to the next process to realize the continuous production of the production line.

7. Organic fertilizer packaging machine

The use of organic fertilizer packaging machines for automatic packaging can not only improve production efficiency, but also reduce labor costs, improve product quality and ensure product hygiene and safety. “

.jpg)