Organic Fertilizer Roaster

Send email to us

Previous:

Organic material drying equipment

Next:

Organic Fertilizer Hot Air Dryer

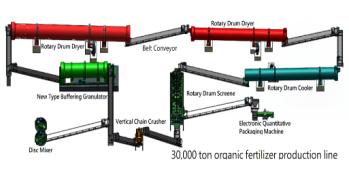

An organic fertilizer roaster is not a common term in the organic fertilizer production process. It is possible that it refers to a type of equipment that is used to dry and sterilize organic materials before they are used in the production of organic fertilizer. However, the more commonly used equipment for drying organic materials in organic fertilizer production is a rotary dryer or a fluid bed dryer. These dryers use hot air to dry the organic materials and remove any moisture that may be present. Once the organic materials are dried, they can be further processed into organic fertilizer.

Write your message here and send it to us