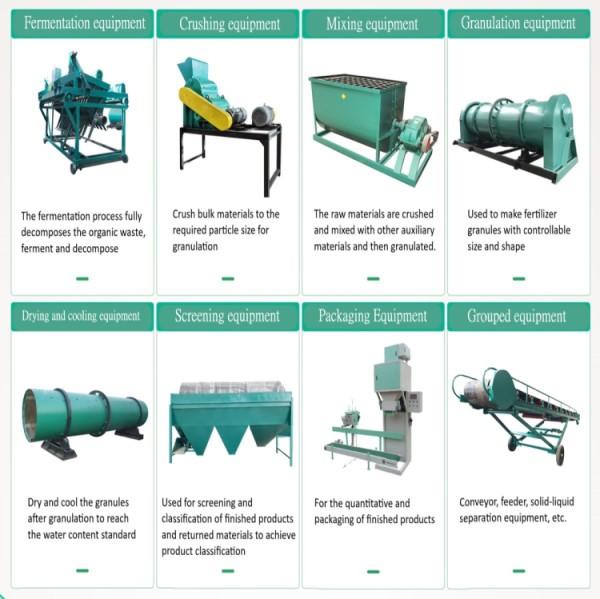

Organic fertilizer production process equipment

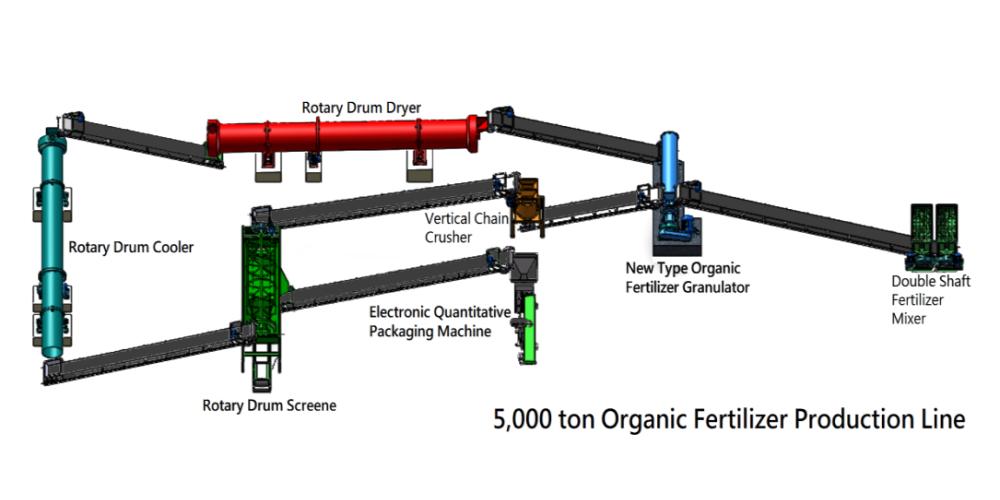

The organic fertilizer production process generally involves the following equipment:

1.Composting Equipment: Composting is the first step in the organic fertilizer production process. This equipment includes organic waste shredders, mixers, turners, and fermenters.

2.Crushing Equipment: The composted materials are crushed using a crusher, grinder, or mill to obtain a homogeneous powder.

3.Mixing Equipment: The crushed materials are mixed using a mixing machine to obtain a uniform mixture.

4.Granulating Equipment: The mixed material is then granulated using an organic fertilizer granulator to obtain the desired particle size and shape.

5.Drying Equipment: The granulated material is then dried using a dryer to reduce the moisture content to the desired level.

6.Cooling Equipment: The dried material is cooled using a cooler to prevent caking.

7.Screening Equipment: The cooled material is then screened using a screening machine to remove any oversize or undersize particles.

8.Coating Equipment: The screened material is coated using a coating machine to improve the quality of the fertilizer.

9.Packaging Equipment: The coated material is then packed using a packaging machine for storage or transportation.

Note that the specific equipment used in the organic fertilizer production process may vary depending on the scale of the operation and the specific needs of the producer.