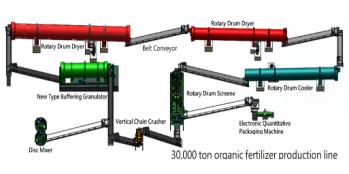

Organic fertilizer production line

An organic fertilizer production line is a series of machines and equipment used to convert organic materials into organic fertilizer products. The production line typically includes the following steps:

1.Pre-treatment: The organic materials such as animal manure, plant residues, and food waste are pre-treated to remove contaminants and to adjust their moisture content to the optimal level for composting or fermentation.

2.Composting or Fermentation: The pre-treated organic materials are then placed in a composting bin or fermentation tank to undergo the biological process of composting or fermentation, which breaks down the organic materials and converts them into a stable, nutrient-rich material called compost.

3.Crushing: The composted or fermented material may then be passed through a crusher or shredder to reduce the size of the particles for further processing.

4.Mixing: The crushed compost may then be mixed with other organic materials, such as crop residues or bone meal, to create a balanced fertilizer blend.

5.Granulating: The mixed fertilizer is then fed into a granulating machine, which compresses the material into granules or pellets for ease of storage and application.

6.Drying: The granulated fertilizer is then dried to remove excess moisture, which prevents the growth of bacteria and prolongs the shelf life of the fertilizer. This may be done using a variety of drying equipment such as rotary dryers, fluidized bed dryers, or drum dryers.

7.Cooling: The dried fertilizer may then be passed through a cooler to reduce the temperature of the fertilizer and prepare it for packaging.

8.Packaging: The finished organic fertilizer is then packaged and labeled for storage or sale.

An organic fertilizer production line may also include additional steps such as screening, coating, or adding microbial inoculants to enhance the quality and efficacy of the finished fertilizer product. The specific equipment and steps used in an organic fertilizer production line may vary depending on the scale of production, the type of organic materials being used, and the desired characteristics of the finished fertilizer product.