Organic fertilizer production line

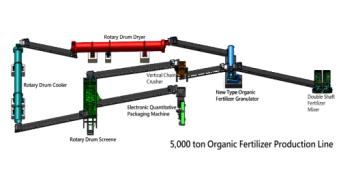

An organic fertilizer production line typically includes several key steps and components. Here are the main components and processes involved in an organic fertilizer production line:

1.Raw material preparation: This involves collecting and preparing the organic materials used in the production of the fertilizer. These materials can include animal manure, compost, food waste, and other organic wastes.

2.Crushing and mixing: In this step, the raw materials are crushed and mixed to ensure that the final product has a consistent composition and nutrient content.

3.Granulation: The mixed materials are then fed into an organic fertilizer granulator, which shapes the mixture into small, uniform pellets or granules.

4.Drying: The freshly formed fertilizer granules are then dried to reduce moisture content and increase shelf life.

5.Cooling: The dried granules are cooled to prevent them from clumping together.

6.Screening: The cooled granules are then screened to remove any oversized or undersized particles and ensure that the final product is of uniform size.

7.Coating and packaging: The final step involves coating the granules with a protective layer and packaging them for storage or sale.

Depending on the specific requirements and production capacity, an organic fertilizer production line may also include additional steps, such as fermentation, sterilization, and quality control testing. The exact configuration of the production line will vary based on the needs of the manufacturer and the end users of the fertilizer product.