Organic fertilizer production line

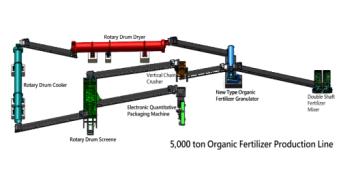

An organic fertilizer production line typically includes several stages of processing, each involving different machines and equipment. Here is a general overview of the process:

1.Pre-treatment stage: This involves collecting and sorting the organic materials to be used in the production of fertilizer. The materials are typically shredded and mixed together.

2.Fermentation stage: The mixed organic materials are then placed in a fermentation tank or machine, where they undergo a natural decomposition process. During this stage, bacteria break down the organic matter into simpler compounds, producing heat and carbon dioxide as byproducts.

3.Crushing and mixing stage: Once the organic materials have been fermented, they are passed through a crusher and then mixed with other ingredients such as minerals and trace elements to create a balanced fertilizer.

4.Granulation stage: The mixed fertilizer is then granulated using a granulation machine, such as a disc granulator, rotary drum granulator or extrusion granulator. The granules are typically between 2-6 mm in size.

5.Drying and cooling stage: The newly formed granules are dried and cooled using a drying machine and cooling machine, respectively.

6.Screening and packaging stage: The final step involves screening the granules to remove any oversized or undersized particles, and then packaging them in bags or other containers for distribution.

The entire process can be automated with the use of a control system, and the production line can be customized to suit the specific needs of the manufacturer.