Organic fertilizer line

An organic fertilizer production line is a comprehensive system designed to convert organic materials into high-quality organic fertilizers. With a focus on sustainability and environmental stewardship, this production line utilizes various processes to transform organic waste materials into valuable fertilizers rich in nutrients.

Components of an Organic Fertilizer Production Line:

Organic Material Pre-processing: The production line begins with the pre-processing of organic materials such as animal manure, crop residues, food waste, and green waste. This involves shredding, grinding, or composting to break down the materials into smaller particles and ensure an optimal starting point for the subsequent processes.

Fermentation Process: The pre-processed organic materials undergo a fermentation process, also known as composting or maturation. During this phase, microorganisms naturally break down the organic matter, converting it into a nutrient-rich compost. Proper temperature, moisture, and oxygen levels are maintained to facilitate the microbial activity and accelerate the decomposition process.

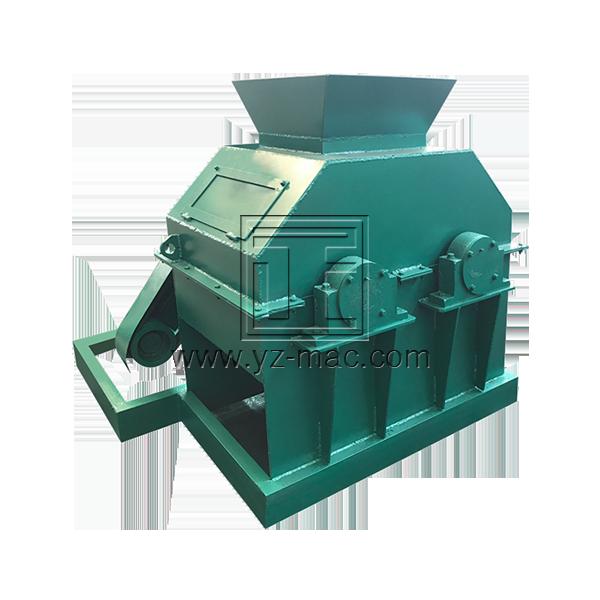

Crushing and Mixing: Once the composting process is complete, the fermented organic matter is crushed into finer particles to ensure uniformity. This is followed by the mixing of various organic materials, such as compost, crop residues, and bio-degradable waste, to create a balanced and nutrient-rich mixture.

Granulation: The mixed organic material is then passed through a granulation machine, which shapes the mixture into granules. This process improves the handling, storage, and application of the organic fertilizer while also enhancing its nutrient release characteristics.

Drying and Cooling: The freshly formed organic fertilizer granules are dried and cooled to remove excess moisture and prevent clumping. This step ensures the stability and shelf life of the final product.

Screening and Packaging: The dried organic fertilizer granules undergo screening to remove any oversized or undersized particles, ensuring a consistent product size. The screened granules are then packaged into bags or other containers for distribution and sale.

Benefits of an Organic Fertilizer Production Line:

Nutrient-rich Fertilizers: The organic fertilizer production line enables the transformation of organic waste materials into nutrient-rich fertilizers. These fertilizers provide essential macronutrients (nitrogen, phosphorus, and potassium) and micronutrients necessary for plant growth, promoting soil fertility and crop productivity.

Waste Recycling and Environmental Sustainability: By utilizing organic waste materials, the production line contributes to waste recycling and minimizes the environmental impact associated with organic waste disposal. It helps reduce landfill usage, greenhouse gas emissions, and water pollution, fostering a more sustainable approach to agriculture.

Soil Health and Nutrient Cycling: Organic fertilizers derived from the production line enhance soil health by improving soil structure, water-holding capacity, and microbial activity. These fertilizers also promote nutrient cycling, as they release nutrients slowly and steadily, reducing the risk of nutrient leaching and runoff.

Crop Quality and Flavor: Organic fertilizers produced through this line contribute to improved crop quality, taste, and nutritional value. They enhance the natural flavors, aromas, and nutrient profiles of fruits, vegetables, and other crops, meeting the increasing consumer demand for organic and healthy produce.

An organic fertilizer production line plays a vital role in sustainable agriculture by converting organic waste materials into valuable organic fertilizers. This comprehensive system integrates processes such as pre-processing, fermentation, crushing, mixing, granulation, drying, and packaging to create nutrient-rich fertilizers while minimizing environmental impacts. The line’s benefits include nutrient-rich fertilizers, waste recycling, soil health improvement, and enhanced crop quality.