Online Exporter Ring Die Granulator - New Type Organic & Compound Fertilizer Granulator – YiZheng

Online Exporter Ring Die Granulator - New Type Organic & Compound Fertilizer Granulator – YiZheng Detail:

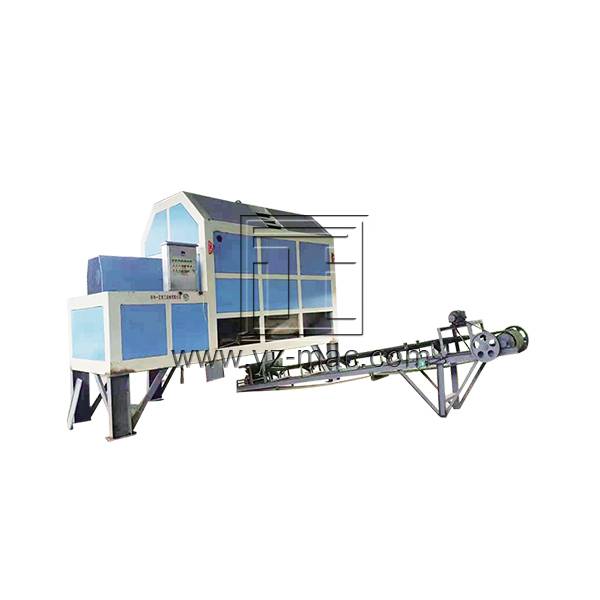

The New Type Organic & Compound Fertilizer Granulator is a granulation equipment commonly used in the production of compound fertilizers, organic fertilizers, biological fertilizers, controlled release fertilizers, etc. It is suitable for large-scale cold and hot granulation and high, medium and low concentration compound fertilizers produce.

The main working mode is granulation wet granulation. Through quantitative water or steam, the basic fertilizer is fully chemically reacted after being conditioned in the cylinder. Under the set liquid conditions, the rotation of the cylinder is used to make the material particles Produces a crushing force to agglomerate into balls.

This New Type Organic & Compound Fertilizer Granulator is a new patented product developed by our company and the Agricultural Machinery Research Institute. The machine can not only granulate a variety of organic matter, especially for fiber materials which are difficult to be granulated by conventional equipment, such as crop straw, wine residue, mushroom residue, drug residue, animal dung and so on. The granulation can be made after fermentation, and it also can be achieved the better effect of grain making to acid and municipal sludge.

The ball formation rate is up to 70%, the ball strength is high, there is a small amount of return material, the return material size is small, and the pellet can be re-granulated.

10,000-300,000 tons/year NPK compound fertilizer production line

10,000-300,000 tons/year organic fertilizer production line

10,000-300,000 tons/year bulk blending fertilizer production line

10,000-300,000 tons/year Ammonia-acid process, Urea based compound fertilizer production line

10,000-200,000 tons/year animal manure, food waste, sludge and other organic waste treatment and granulation equipment

|

Model |

Bearing Model |

Power (KW) |

Overall Size (mm) |

|

FHZ1205 |

22318/6318 |

30/5.5 |

6700×1800×1900 |

|

FHZ1506 |

1318/6318 |

30/7.5 |

7500×2100×2200 |

|

FHZ1807 |

22222/22222 |

45/11 |

8800×2300×2400 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

The fermentation process of organic compost is actually the process of metabolism and reproduction of various microorganisms. The metabolic process of microorganisms is the process of decomposition of organic matter. Decomposition of organic matter necessarily generates energy, which drives the composting process, increasing the temperature, and also drying the wet substrate. Online Exporter Ring Die Granulator - New Type Organic & Compound Fertilizer Granulator – YiZheng , The product will supply to all over the world, such as: Costa Rica, Muscat, Cannes, Cow dung milling machine, organic fertilizer production line factory direct sales ex-factory price, supply all kinds of organic fertilizer equipment series supporting products, provide free consultation on the construction of a complete production line of organic fertilizer production line. And provide professional consulting services.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!