OEM Supply Homemade Compost Turner - Wheel Type Composting Turner Machine – YiZheng

OEM Supply Homemade Compost Turner - Wheel Type Composting Turner Machine – YiZheng Detail:

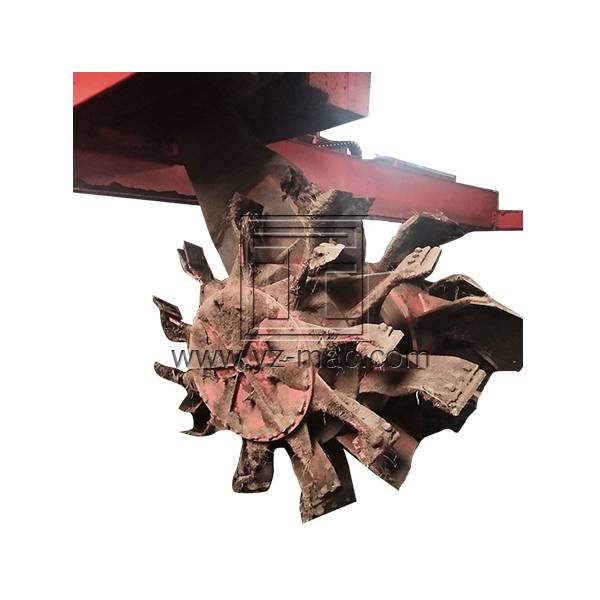

Wheel Type Composting Turner Machine is an important fermentation equipment in large scale organic fertilizer making plant. The wheeled compost turner can rotate forward, backward and freely, all of which are operated by one person. Wheeled composting wheels work above tape compost stacked in advance; the rotary knives installed on strong rotating drums under the tractor rack are tools for mixing, loosening or moving stacking stacks.

Wheel Type Composting Turner Machine are widely used in fermentation and water removal operations such as organic fertilizer plants, compound fertilizer plants, sludge and garbage factories, garden farms and mushroom plants.

1. Suitable for aerobic fermentation, it can be used in conjunction with solar fermentation chambers, fermentation tanks and shifters.

2. Products obtained from high-temperature aerobic fermentation can be used for soil improvement, garden greening, landfill cover, etc.

1. Wheel Type Composting Turner Machine can move forward, backward and turn freely and all these moves are manipulated by one person.

2. The bio-organic materials should be piled first on the ground or in workshops in a strip shape.

3. Compost turner works by bestriding above the strip compost piled in advance; rotating knives installed on a strong rotary drum under the tractor rack are the exact tools to blend, loosen or move piled compost.

4. After turning, a new strip compost pile is formed and wait to continue fermentation.

5. There is compost thermometer to measure compost temperature so as to a second time turning.

1. The high turning depth: the depth can be 1.5-3m;

2. The large turning span: the largest width can be 30m;

3. The low energy consumption: adopt unique energy efficient transmission mechanism, and the energy consumption of the same operating volume is 70% lower than that of the traditional turning equipment;

4. Turning with no dead angle: the turning speed is in symmetry, and under the displacement of the governor shift trolley, there is no dead angle;

5. High degree of automation: it is equipped with fully automated electrical control system, when the turner is working without the need for an operator.

|

Model |

Main power (kw) |

Mobile motor power supply (kw) |

Tramless power (kw) |

Turn width (m) |

Turn depth (m) |

|

YZFDLP-20000 |

45 |

5.5*2 |

2.2*4 |

20 |

1.5-2 |

|

YZFDLP-22000 |

45 |

5.5*2 |

2.2*4 |

22 |

1.5-2 |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Complete production equipment for organic fertilizer

6. Screening equipment: trommel screening machine OEM Supply Homemade Compost Turner - Wheel Type Composting Turner Machine – YiZheng , The product will supply to all over the world, such as: Turkey, Florida, Saudi Arabia, Organic fertilizer crushing equipment, fertilizer crushing equipment, is widely used in the production process of organic fertilizer, and has a good crushing effect on wet raw materials such as chicken manure and sludge.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.