OEM Factory for Fertilizer Crusher Price - Straw & Wood Crusher – YiZheng

OEM Factory for Fertilizer Crusher Price - Straw & Wood Crusher – YiZheng Detail:

The Straw & Wood Crusher on the basis of absorbing the advantages of many other kinds of crusher and adding the new function of cutting disc, it makes full use of crushing principles and combine the crushing technologies with hit, cut, collision and grind.

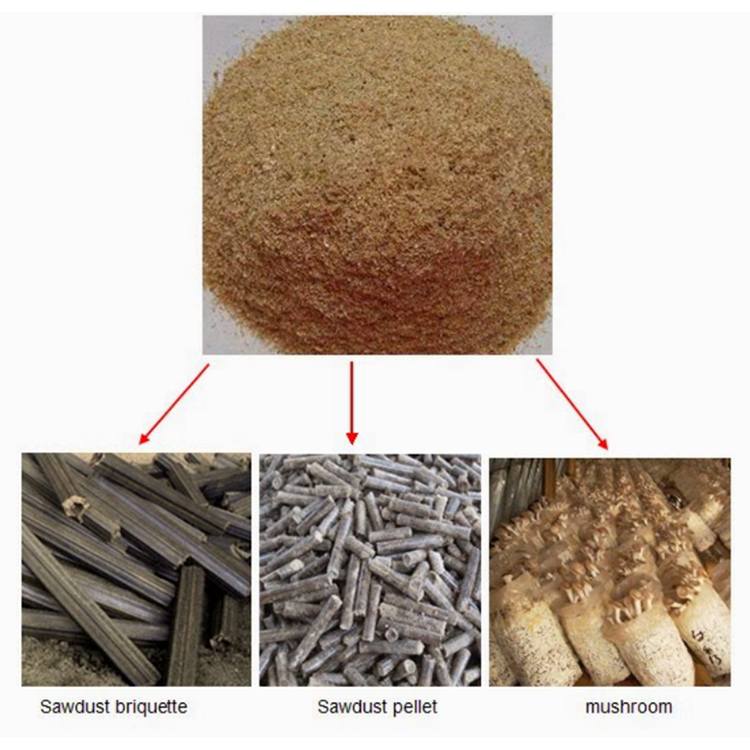

The Straw & Wood Crusher can be used for crushing bamboo, branches, bark, leaves, scraps, scraps, rice husk, sawdust, formwork, corn cob, straw, cotton, etc., and also widely more widely applicated in paper making, edible fungus, mechanism charcoal, particleboard, sawdust, high-density board, medium fiber board and other industrial production.

The Straw & Wood Crusher is known as multi-functional scrap crusher such as wood crusher, small branches crusher, double port crusher. It integrates the advantages of the hammer wood crusher and the cutting-disc wood crusher. One feeding port feed the log, another feeding port feed the branches, board waste materials and so on. It processes the raw materials which diameter less than 250mm into sawdust size at 1-40mm.

(1) It has low investment, low energy consumption, high productivity, good economic benefits, and convenient use and maintenance

(2) Multi-functional Straw & Wood Crusher with high production efficiency, simple use, convenient maintenance and wide feeding range

(3) The Straw & Wood Crusher can be used as a supporting machine for the processing and production of edible fungus culture materials and the industrial production preparation of paper mills, fiberboard plants, particleboard plants, and MDF plants.

(4) The Straw & Wood Crusher combines the advantages of hammer-type wood crushing machine and knife-disc wood crushing machine.

(5) Optional electrical motor/diesel motor according to actual needs;

(6) Optional wheels mounting and provide other customized designs.

|

Parameters of Straw& Wood Crusher |

||||

|

Model |

500 Type |

600 Type |

800 Type |

1000 Type |

|

Rotating diameter of cutter head(mm) |

500 |

600 |

800 |

1000 |

|

Number of smashing cutters (pieces) |

12 |

24 |

32 |

48 |

|

Number of cutting blades (hands) |

4 |

4 |

4 |

4 |

|

Flat inlet size |

500×350 |

600×350 |

800×350 |

1000×450 |

|

Spindle speed (rev/min) |

2600 |

2600 |

2400 |

2000 |

|

Power(kw) |

15 |

22 |

37 |

55 |

|

Capacity(t/h) |

0.6 |

1.5 |

2.0–2.5 |

3.5–4.5 |

|

Note: The mobile diesel engine power can be made according to the actual needs. |

||||

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

Small fermentation compost machine, organic fertilizer turner, hydraulic trough turner, furfural residue compost turner, organic fertilizer turner, organic fertilizer tank. OEM Factory for Fertilizer Crusher Price - Straw & Wood Crusher – YiZheng , The product will supply to all over the world, such as: Naples, Portugal, Netherlands, The organic fertilizer mixer is used for granulation after the raw materials are pulverized and mixed with other auxiliary materials evenly. During the churning process, mix the powdered compost with any desired ingredients or recipes to increase its nutritional value. The mixture is then granulated using a granulator.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!