NPK compound fertilizer production line

NPK compound fertilizer production line

NPK compound fertilizer is a compound fertilizer that is mixed and batched according to different proportions of a single fertilizer, and a compound fertilizer containing two or more elements of nitrogen, phosphorus and potassium is synthesized by chemical reaction, and its nutrient content is uniform and the particle size is consistent. The compound fertilizer production line has a wide range of adaptability to the granulation of various compound fertilizer raw materials.

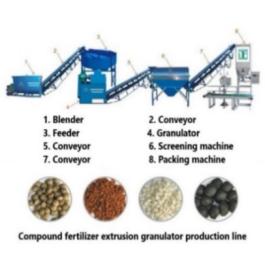

The equipment required for NPK compound fertilizer production line usually includes:

1. Mixing equipment: horizontal mixer, double shaft mixer

- After the raw materials are crushed, they are mixed with other auxiliary materials and then granulated.

2. Crushing equipment: vertical crusher, cage crusher, double shaft chain mill

- The pulverizer is widely used in the production process of organic fertilizer, and has a good pulverizing effect on wet raw materials such as chicken manure and sludge.

3. Granulation equipment: drum granulator, roller extrusion granulator

- The granulation process is the core part of the organic fertilizer production line. The granulator achieves high-quality and uniform granulation through the continuous process of stirring, collision, inlay, spheroidization, granulation, and densification.

4. Drying equipment: tumble dryer, dust collector

- The dryer makes the material fully contact with the hot air to reduce the moisture content of the particles.

5. Cooling equipment: drum cooler, dust collector

- The cooler reduces the water content of the pellets again while reducing the pellet temperature.

6. Screening equipment: trommel screening machine

- Both powders and granules can be screened out by trommel screening machine.

7. Coating equipment: coating machine

- Equipment for coating powder or liquid on the surface of fertilizer particles to realize the coating process.

8. Packaging equipment: automatic packaging machine

- Automatic quantitative packaging machine can automatically weigh, convey and seal bags.