Non-drying extrusion compound fertilizer production equipment

Non-drying extrusion compound fertilizer production equipment is used to produce compound fertilizers through a process called extrusion. This equipment can be composed of several different machines and tools, depending on the scale of production and the level of automation desired. Here are some basic equipment that can be used to produce non-drying extrusion compound fertilizer:

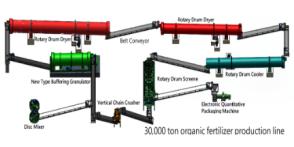

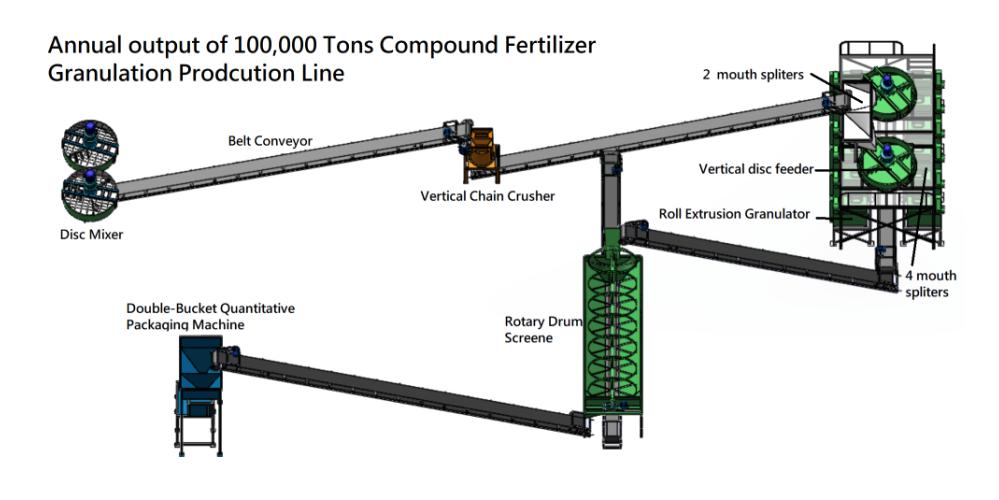

1.Crushing Machine: This machine is used to crush the raw materials into smaller particles, which can help to improve the quality of the finished fertilizer.

2.Mixing Machine: After the raw materials are crushed, they are mixed together to create a balanced fertilizer mixture. A mixing machine can help to ensure that the ingredients are thoroughly mixed.

3.Extrusion Machine: This machine is used to extrude the mixed materials into cylindrical or spherical pellets, which are then dried and coated with a protective layer. The extrusion process can help to improve the density and hardness of the fertilizer, which can improve its effectiveness.

4.Drying Machine: Once the extruded pellets are formed, a drying machine can be used to remove excess moisture and create a more stable product.

5.Coating Machine: This machine can be used to coat the finished fertilizer pellets with a thin layer of protective material, which can help to prevent moisture loss and improve nutrient absorption.

6.Packing Machine: A packing machine can be used to pack the finished compound fertilizer into bags or containers, which makes it easier to transport and sell.

It is important to note that these machines are just examples of equipment that can be used to produce non-drying extrusion compound fertilizer. The specific equipment needed will depend on the scale of production and the specific requirements of the production process. Additionally, the formulation of the fertilizer can also require specialized equipment for mixing and handling of raw materials.