A vibrating screening machine is a commonly used equipment for particle separation and classification. It works by placing granular materials on a screening surface, where vibration forces cause the particles to move, separate, and classify according to size. This equipment is highly effective for screening and grading various materials such as granules, powders, and colloids. Common types include circular vibrating screens, linear vibrating screens, and high-frequency vibrating screens.

I. Product Overview:

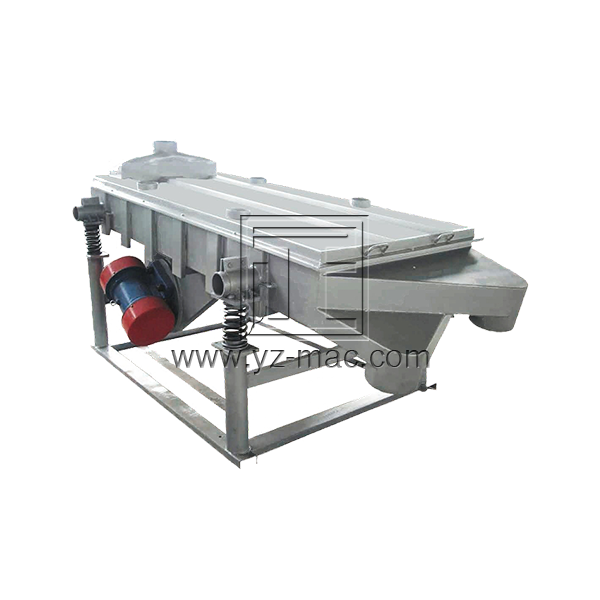

The Fertilizer Vibrating Screening Machine is a key classification device widely applied in the production lines of organic fertilizers, compound fertilizers, bio-fertilizers, and various granular fertilizers. Its primary function is to classify fertilizer granules by size and remove impurities after granulation, drying, and cooling. This ensures uniform particle distribution, clean appearance, and consistent product quality. By using high-frequency vibration to achieve precise classification, the machine significantly enhances automation levels, reduces labor costs, and minimizes screening errors.

As modern agriculture advances toward efficiency, sustainability, and smart production, fertilizer granule uniformity has become a key market competitiveness indicator. Traditional manual or rotary drum screening methods suffer from low efficiency, screen clogging, and inconsistent precision. The vibrating screening machine overcomes these limitations through multi-layer screening surfaces and adjustable vibration frequency technology, allowing accurate screening of materials with varying particle sizes, moisture content, and textures. It is now an indispensable component for fertilizer producers aiming to improve both quality and capacity.

Zhengzhou Yizheng Heavy Machinery Co., Ltd. designs and manufactures high-reliability vibrating screens known for excellent performance, stable operation, and long service life. Drawing from extensive industry experience, Yizheng’s models are ideal for small, medium, and large fertilizer production lines, making them the preferred choice for modern fertilizer plants.

II. Working Principle:

The core principle of the vibrating screening machine is to generate vibration forces through an excitation device, causing the material to move in a jumping motion across the screen surface, achieving classification and separation. The system typically consists of a screen box, vibrating motor, damping device, frame, and control system.

1. Excitation Drive

Equipped with dual vibrating motors or a single-shaft exciter, the system produces centrifugal inertial force during high-speed rotation, driving the screen box to vibrate periodically. Adjusting the motor’s eccentric weight and frequency controls the amplitude and material trajectory to suit different fertilizer characteristics.

2. Material Motion and Classification

Fertilizer granules fed onto the screen surface move directionally under vibration. Small particles fall through the screen openings to form undersized products, while larger ones move forward for discharge. Double- or triple-layer screens are commonly used to obtain two or three distinct particle size fractions simultaneously.

3. Screen Mesh and Anti-Clogging Design

The screens can be made of stainless steel woven mesh, perforated steel plates, or polyurethane anti-blocking panels with anti-adhesion coatings, ideal for moist or sticky fertilizer granules. The quick-release frame design simplifies replacement and cleaning.

4. Damping and Support System

Rubber springs or composite dampers beneath the screen box absorb vibration effectively, reducing operational noise and structural load. The system maintains excellent dynamic balance, allowing continuous operation without resonance.

5. Intelligent Control System

Advanced models can be equipped with PLC-based control, enabling automatic start/stop, throughput monitoring, clog detection, and frequency adjustment. Integration with remote monitoring systems supports intelligent production management.

III. Product Applications:

The vibrating screening machine has broad applications across fertilizer processing and other industries involving granular or powder materials. Key uses include:

1. Organic Fertilizer Production Lines

Classifies fermented, granulated, and dried organic fertilizer particles, removing unformed or broken granules to ensure uniform, high-quality output.

2. Compound and Inorganic Fertilizer Lines

Used after granulation and cooling to eliminate fines and oversized particles, improving appearance and gradation consistency before packaging.

3. Bio-Organic and Microbial Fertilizer Production

Suitable for materials containing active microorganisms; gentle vibration ensures screening without damaging microbial viability or reducing fertilizer effectiveness.

4. Livestock Manure Composting Systems

Performs pre-screening and impurity removal after composting, separating undecomposed lumps and non-organic residues to enhance granulation efficiency.

5. Feed, Chemical, and Recycling Industries

Applicable for classifying feed ingredients, chemical powders, and dried sludge particles—demonstrating high versatility beyond fertilizer use.

IV. Product Features:

1. High Screening Efficiency and Adjustable Precision

Dual vibration excitation technology achieves over 90% screening efficiency. Vibration amplitude and screen inclination can be adjusted for multi-specification fine screening.

2. Robust Construction and Stable Operation

Built from high-strength welded steel with dynamically balanced components, the machine operates smoothly without resonance—ideal for continuous, long-term operation.

3. Strong Adaptability and Wide Application Range

Suitable for powder, granular, moist, or dry materials; particularly effective for sticky or wet organic fertilizer particles.

4. Anti-Clogging and Self-Cleaning Design

Equipped with rubber ball cleaning devices under the screen surface to prevent clogging and ensure consistent efficiency.

5. Easy Maintenance and Long Service Life

Simple motor maintenance, dust-proof bearings, quick-release screen mesh design, and anti-corrosion treatment make it ideal for humid environments.

6. Superior Energy Efficiency and Environmental Compliance

Fully sealed structure minimizes dust emissions; optional negative-pressure dust collection system supports green, clean production in line with environmental standards.

7. Low Noise and Safe Operation

Combined damping and noise-reduction design keeps sound levels below 75 dB. Safety covers and emergency stop systems ensure operator protection.

8. Automation and Smart Control Options

Integrates seamlessly with plant automation systems for real-time monitoring, data logging, and operational feedback, enhancing factory-level digitalization.

9. Customizable Design Solutions

Zhengzhou Yizheng offers tailor-made configurations based on capacity, material characteristics, and plant layout — including screen layer count, mesh size, outlet height, and connection types.

10. High Compatibility and System Integration

The screening machine connects easily with granulators, dryers, coolers, and packaging systems, forming a complete automated fertilizer production line for continuous high-throughput operation.

As an essential component in the fertilizer post-processing stage, the vibrating screening machine directly influences the final product quality and market grade. Its high efficiency, structural stability, and intelligent control make it a core device for enhancing productivity and consistency in modern fertilizer manufacturing.

With years of expertise in fertilizer machinery, Zhengzhou Yizheng Heavy Machinery Co., Ltd. provides a wide range of vibrating screen models and configurations—from small pilot systems to large-scale continuous production lines. Upholding the principles of efficiency, energy conservation, and intelligent design, Yizheng delivers reliable, high-performance screening solutions that empower the organic and compound fertilizer industries to achieve sustainable and high-quality growth.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Nov-11-2025