I. Product Overview

The fertilizer screening machine is a core piece of equipment in fertilizer production lines, responsible for finished product grading, quality control, and process stability. It is primarily used for particle size classification, impurity separation, and specification sorting of fertilizer granules after granulation, drying, or cooling. Its operating performance directly affects particle uniformity, appearance quality, and commercial grade of finished fertilizers, making it an indispensable link between the granulation system and the packaging system.

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd., as a professional manufacturer of fertilizer equipment, has long been dedicated to the research, development, and manufacturing of complete production line equipment for organic fertilizers, compound fertilizers, and bio-organic fertilizers. The fertilizer screening machines produced by Yizheng are widely applied in various fertilizer production lines, covering organic fertilizer, bio-organic fertilizer, compound fertilizer, and organic–inorganic compound fertilizer, and can adapt to different material characteristics and production capacity requirements.

In modern fertilizer industry, fertilizer products are not only required to have scientifically balanced nutrient formulations, but also emphasize regular particle shape, uniform particle size, and attractive packaging appearance. Through stable and continuous grading operations, fertilizer screening machines effectively control finished product specifications, promptly separate and recycle unqualified particles, thereby improving overall production line efficiency and product qualification rate. Yizheng’s screening equipment has been validated through long-term industrial practice in terms of structural design, screening accuracy, and operational stability, fully meeting the practical requirements of large-scale and continuous fertilizer production.

II. Working Principle

The working principle of the fertilizer screening machine is based on the different passing capabilities of granular materials under mechanical motion due to particle size variations, thereby achieving automatic classification. According to process configurations and material characteristics of fertilizer production lines, Yizheng fertilizer screening machines typically adopt vibration screening or rotary drum screening, and can also be designed in combined configurations as required.

1.Vibrating Fertilizer Screening Machine

In vibrating screening machines, directional excitation force is generated by vibration motors or excitation devices, causing the screen box to vibrate continuously along a preset trajectory. After fertilizer granules enter the screen surface, they move forward under the combined action of vibration force and gravity. Particles smaller than the screen aperture pass through the screen mesh and become qualified products or enter the next process stage, while particles larger than the aperture continue moving along the screen surface and are discharged from another outlet into the return or reprocessing system. By configuring double-layer or multi-layer screens, multi-size particle classification can be completed in a single operation.

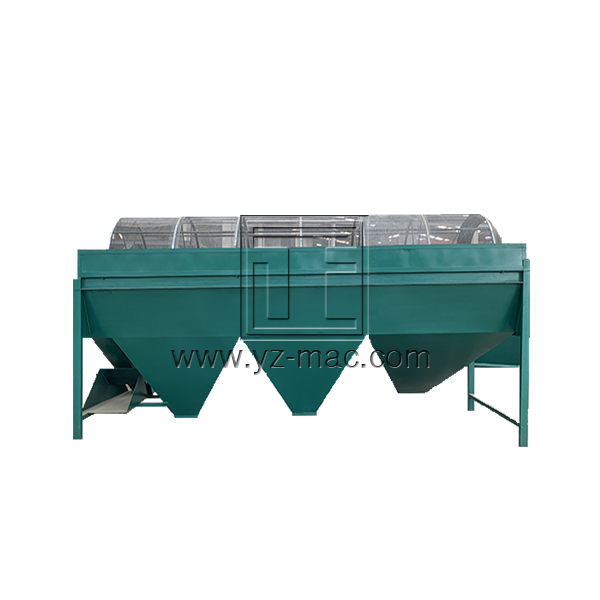

2.Rotary Drum Fertilizer Screening Machine

The rotary drum screening machine completes classification through the slow rotation of a cylindrical screen body. Materials continuously tumble, lift, and fall inside the drum, allowing smaller particles to pass through the screen holes first, while larger particles gradually move toward the discharge end. This screening method operates smoothly with minimal impact on materials, making it particularly suitable for organic fertilizers with higher moisture content or materials prone to agglomeration.

In actual production, fertilizer screening machines usually operate in coordination with return conveying systems, crushing systems, and automatic control systems, forming a complete closed-loop grading and return process to ensure continuous, stable, and efficient operation of the production line.

III. Product Applications

Fertilizer screening machines manufactured by Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd. feature broad applicability and can be flexibly configured in various types of fertilizer production lines. Typical applications include:

Used for screening and grading organic fertilizer granules after fermentation and granulation, removing oversized particles and fine powder to improve particle uniformity and commercial appearance.

- Bio-Organic Fertilizer Production Systems

Suitable for screening fertilizer granules containing microbial agents. The smooth screening process effectively reduces particle breakage and helps maintain the stability of active components.

Used for size classification of granules produced by extrusion granulation, rotary drum granulation, or spray granulation, with unqualified particles returned to crushing or granulation sections.

- Livestock and Poultry Manure Resource Utilization Projects

Applied for pre-screening and finished product screening of fermented manure materials, removing incompletely decomposed lumps and improving subsequent granulation and packaging efficiency.

- Agricultural Mineral and Functional Fertilizer Processing

Suitable for grading humic acid fertilizers, mineral fertilizers, controlled-release fertilizers, and other granular products to meet different fertilization method requirements.

- Supporting Equipment for Complete Fertilizer Production Lines

Can be seamlessly integrated with granulators, dryers, coolers, and packaging machines to form continuous and automated fertilizer production processes.

IV. Product Features

- High Screening Accuracy and Stable Product Specifications

Scientifically designed screen apertures and screening structures effectively control finished product particle size range, significantly improving product consistency and qualification rate.

- Reasonable Structure and Stable Operation

The main structure is manufactured from high-strength steel, with reinforced treatment at key positions, ensuring long-term operation without deformation and suitability for continuous production.

- Multi-Layer Screening Design for Higher Capacity Utilization

Supports double-layer or multi-layer screen configurations, enabling multi-stage classification in one operation, reducing return cycles and increasing overall processing capacity.

- Adaptability to Various Material Characteristics

Whether dry granules, moist organic fertilizers, or materials prone to agglomeration, stable screening can be achieved through appropriate screen and structural configurations.

- Convenient Maintenance and Low Operating Cost

Screens adopt modular installation for quick replacement; transmission systems feature simple structures, resulting in low routine maintenance workload.

- Good Sealing Performance and Environmental Compliance

Optional enclosed structure effectively reduces dust emission and can be integrated with dust collection systems to meet environmental protection standards.

- Customized Design Support

Yizheng can customize screening machine models, screen sizes, number of screen layers, and discharge configurations according to customer capacity, material characteristics, and plant layout.

- Strong Production Line Compatibility

Standardized equipment interfaces facilitate rapid integration with existing or newly built fertilizer production lines, shortening project construction cycles.

As an essential piece of equipment in fertilizer production lines, fertilizer screening machines play a critical role in ensuring product quality and improving production efficiency. With years of manufacturing experience and mature engineering expertise, Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd. provides fertilizer screening solutions featuring stable performance, strong adaptability, and convenient maintenance, helping fertilizer enterprises achieve high-quality, large-scale, and sustainable development.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Feb-10-2026