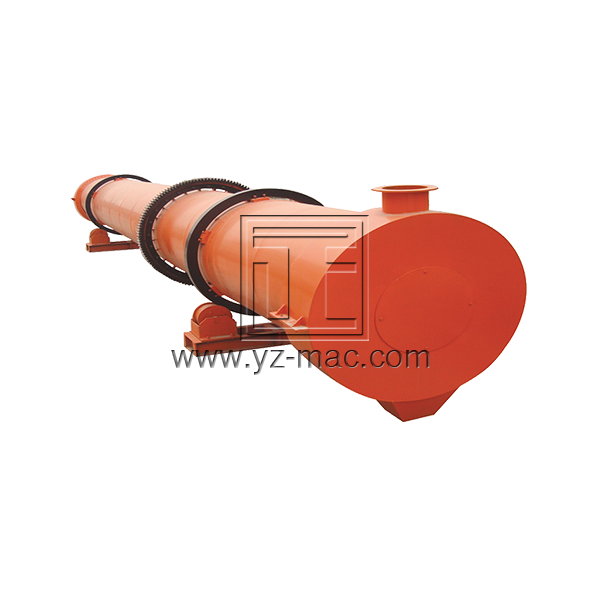

Rotary dryer is the machine for drying the shaped fertilizer-granules. It is one of the key equipment in the fertilizer industry. The induced draft fan at the machine’s tail is continuously pumped the heat from the head-located hot-blast stove towards to the tail. With the continuous rotating of the drum, the internal lifting-plates pick the shaped-granules up and drop them repeatedly through the air stream , the granules and hot air are full contacting to take away the water and achieve the even drying.

The rotary drum dryer can dry up to 30% ~ 50 moisture content of livestock manure to safe storage moisture content. This

The rotary dryer is a commonly used fertilizer drying equipment, suitable for drying various types of fertilizers, including organic fertilizers. Its working principle involves feeding wet materials into the rotating drum, where the rotation of the drum combined with heat from the heating source evaporates the moisture, thus achieving the drying effect.

The rotary dryer is characterized by high drying efficiency, low energy consumption, and easy operation, making it widely applied in the production of fertilizers, food, wood, and other industries.

I. Product Overview

The rotary dryer is a continuous drying device mainly used to reduce the moisture content of granular or powdery materials, thereby improving storage stability and subsequent processing performance. The equipment consists of a rotating drum, lifting plates, a transmission system, feeding and discharging units, a combustion and heating system, and an induced draft dust removal system.

In the fertilizer industry, the rotary dryer is an indispensable post-treatment machine in the granulation process of organic and compound fertilizers. It reduces the moisture content of finished granules from 20%–40% down to below 10%, ensuring that the final product meets national standards.

II. Working Principle

-

Feeding: Materials to be dried are transported into the inclined rotating drum by a conveyor.

-

Hot Air Heating: A hot-air furnace or burner provides high-temperature airflow (either co-current or counter-current), fully contacting the material.

-

Lifting & Tumbling: As the drum rotates, the lifting plates continuously raise, scatter, and tumble the materials, enhancing heat exchange with the hot air and rapidly evaporating moisture.

-

Moisture Exhaust: The evaporated vapor is discharged along with tail gas and purified by dust removal equipment before being released.

-

Discharging: The dried materials exit through the discharge port and can be directly conveyed to cooling or packaging sections.

III. Applications

-

Fertilizer Industry: Organic fertilizer, compound fertilizer, urea, ammonium chloride, ammonium sulfate granule drying

-

Mining: Iron ore powder, copper concentrate, quartz sand, clay, coal powder

-

Agriculture: Straw powder, sawdust, livestock and poultry manure granules

-

Chemical Industry: Gypsum, slag, fly ash, and other chemical powders

IV. Product Features

-

Large Processing Capacity: Single machine can handle 1 ton/hour to over 20 tons/hour, suitable for large-scale continuous production.

-

High Drying Efficiency: Optimized lifting plate design ensures better contact between material and hot air, resulting in uniform drying.

-

Stable Operation: Transmission system adopts gear or reducer drive for reliable performance.

-

Energy-Saving & Eco-Friendly: Equipped with waste heat recovery and dust removal systems, featuring high thermal efficiency and emission compliance.

-

Wide Applicability: Capable of handling powdery, granular, flaky, and block materials.

-

Long Service Life: Drum is made of Q235, Q345, or wear-resistant steel plates, optionally with heat-resistant lining plates.

V. Main Technical Parameters (Range)

-

Diameter: Φ1.2m ~ Φ3.6m

-

Length: 10m ~ 24m

-

Capacity: 1 t/h ~ 20 t/h

-

Rotating Speed: 3 ~ 8 r/min

-

Power: 7.5 kW ~ 75 kW

-

Final Moisture Content: ≤10%

|

Model |

Diameter (mm) | Length (mm) | Installed Dimensions (mm) | Speed (r/min) | Motor type | Power (kw) |

|

YZHG-0880 |

800 | 8000 | 9000×1700×2400 | 6 | Y132S-4 | 5.5 |

|

YZHG-10100 |

1000 | 10000 | 11000×1600×2700 | 5 | Y132M-4 | 7.5 |

|

YZHG-12120 |

1200 | 12000 | 13000×2900×3000 | 4.5 | Y132M-4 | 7.5 |

|

YZHG-15150 |

1500 | 15000 | 16500×3400×3500 | 4.5 | Y160L-4 | 15 |

|

YZHG-18180 |

1800 | 18000 | 19600×3300×4000 | 4.5 | Y225M-6 | 30 |

|

YZHG-20200 |

2000 | 20000 | 21600×3650×4400 | 4.3 | Y250M-6 | 37 |

|

YZHG-22220 |

2200 | 22000 | 23800×3800×4800 | 4 | Y250M-6 | 37 |

|

YZHG-24240 |

2400 | 24000 | 26000×4000×5200 | 4 | Y280S-6 | 45 |

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Aug-24-2025