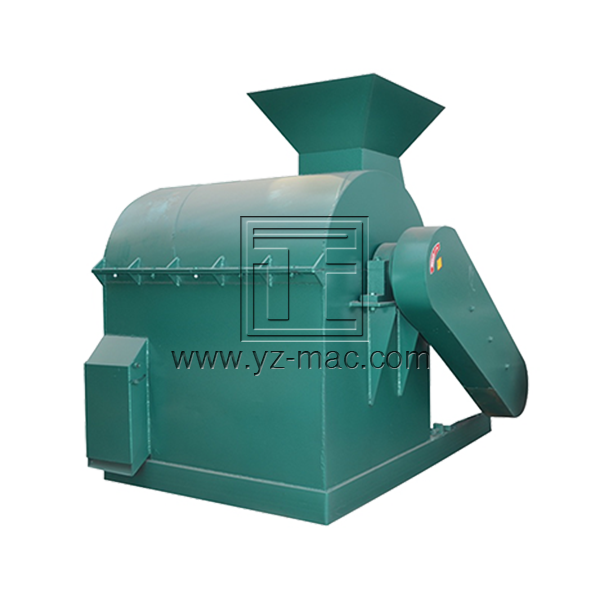

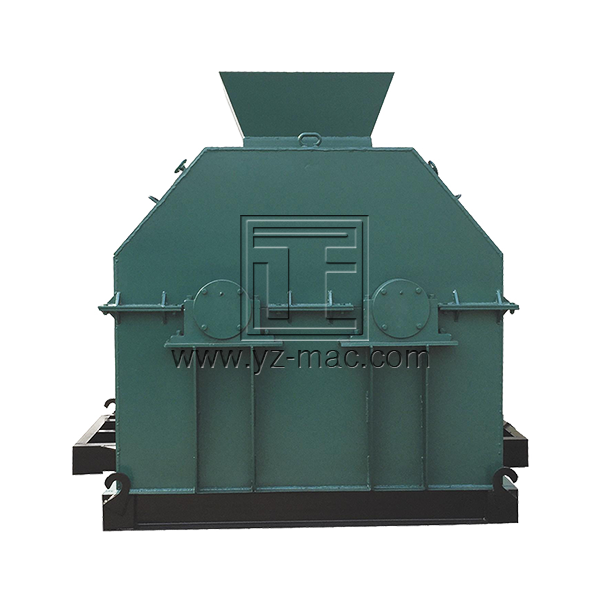

Organic material crushers play an important role in the production of organic fertilizers because they are able to efficiently process raw materials with high humidity, fibrous or low hardness. Organic material crusher is a piece of equipment used to crush organic materials, which is often used in organic fertilizer production lines. It finely crushes organic raw materials to make them easier for subsequent fermentation.

Here are several common types of organic material crushers and their characteristics:

Peculiarity:

It is specially designed for organic materials with high humidity (humidity up to 20%-50%), especially suitable for the crushing of organic materials after fermentation.

The high-speed rotating blade is used to crush the material, with high crushing efficiency and uniform particle size.

It has good anti-clogging ability, and is not easy to jam even when dealing with viscous materials.

Scope of application: chicken manure, cow manure, kitchen waste and other materials with high humidity.

Peculiarity:

A chain that rotates at high speed is used to impact and crush the material.

The structure is simple, easy to maintain, and suitable for medium and low hardness materials.

It is often used in the production of compound fertilizer, and can also be used for the preliminary crushing of some materials in the production of organic fertilizer.

Scope of application: Cooperate with particle processing to process materials with moderate hardness.

3. High humidity straw grinder

3. High humidity straw grinder

Peculiarity:

Specialized in the treatment of straw materials, suitable for waste with high fiber content and high humidity.

Advanced technology can improve the efficiency of fertilizer production and the quality of finished products.

Scope of application: crop straw, forage grass and other fibrous raw materials.

Peculiarity:

It is suitable for materials below medium hardness, and the design of crushing uniformly and without sieve bottom can avoid clogging.

It is suitable for crushing in continuous chemical industry production.

Scope of application: chemical fertilizer raw materials, coal, gypsum and some special raw materials of organic fertilizers.

Key factors in choosing the right crusher:

1. Material characteristics: such as humidity, hardness, fiber content, etc.

2. Production demand: determine the output size and working efficiency of the equipment.

3. Investment budget: Choose the right equipment model according to the performance requirements.

4. Brand and quality: Zhengzhou Yizheng provides a variety of crusher models and reliable quality.

When purchasing an organic material crusher, you need to consider factors such as processing capacity, crushing particle size, energy consumption, noise, and maintenance costs.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Jan-22-2025