I’ product overview

Organic fertilizer shredder is a kind of equipment used to crush and crush organic materials, and the large organic materials are cut and crushed by the shredder machine to obtain uniform and fine organic fertilizer particles. It is usually composed of feed port, crushing chamber, discharge port, motor, etc., and is mainly suitable for waste treatment in organic fertilizer production, crushing and crushing of organic materials, etc.

The benefits of using an organic fertilizer shredder include: improving the utilization rate of organic fertilizer, promoting the decomposition and fermentation of organic matter, shortening the decomposition time of organic materials, and reducing the cost of organic material handling.

Organic fertilizer fragmentation machine is widely used in organic fertilizer, biological fertilizer, compost fermentation and other production processes. It can crush livestock and poultry manure, crop straw, branches and leaves, urban organic waste, fruit and vegetable waste, etc., process the materials into fine crushed forms suitable for fermentation or granulation, and improve the production efficiency and quality of organic fertilizer. The organic fertilizer fragmenter plays a key role in the organic fertilizer production line, ensuring that the raw materials are fully decomposed, accelerating fermentation, and improving the nutrient utilization rate of the finished fertilizer.

There are a few things to pay attention to when using an organic fertilizer shredder machine:

Keep the equipment clean and dry, and regularly maintain and overhaul the equipment;

Select the appropriate crushing degree and crushing speed according to the need;

Pay attention to the safe use of equipment to avoid accidents;

Choose the right equipment specifications and models according to your specific production needs.

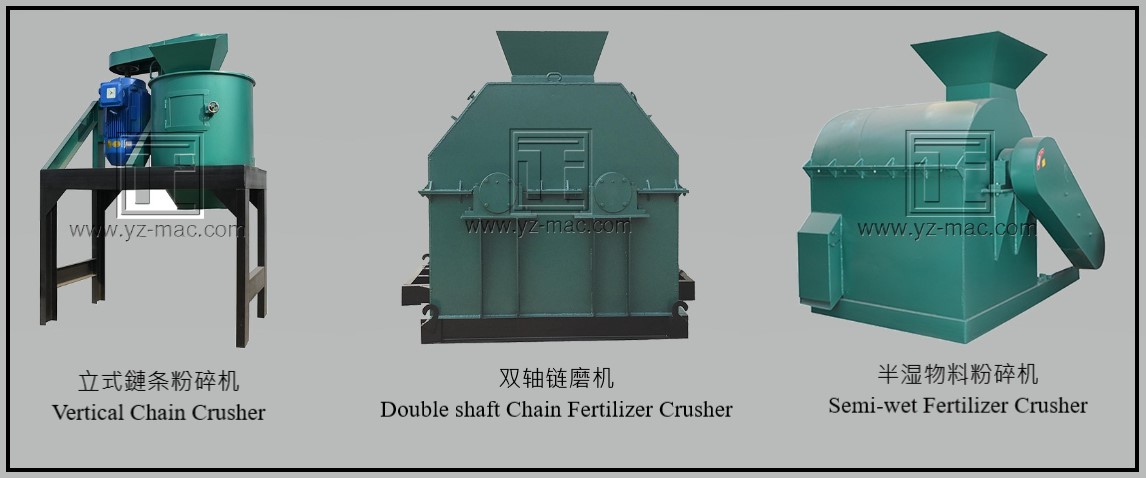

Common organic fertilizer fragmentation machines include cutterhead fragments, hammer fragments, etc.

II’ How it works

The organic fertilizer shredder machine impacts, shears and grinds the organic material through a blade, hammer or chain that rotates at high speed to achieve the crushing effect.

The specific workflow is as follows:

1. Feeding: Through the conveying device or manual feeding, the organic materials are sent into the crushing chamber.

2. Crushing:

Blade grinding: high-speed rotating blades are used to cut materials, which is suitable for fibrous materials, such as straw, branches, etc.

Hammer crushing: high-speed rotating hammer head hits the material to make it crush into fine particles, which is suitable for soft materials such as manure and fruit peel.

Chain grinding: the chain strikes the material, suitable for organic waste of medium hardness.

3. Screening: The crushed material passes through the screen, and the material that meets the requirements enters the next process, and the material that does not meet the requirements returns to continue crushing.

4. Discharging: Qualified finely crushed materials are discharged from the discharge port and enter the subsequent fermentation or granulation process.

III’ Product application

Organic fertilizer shredder machine is suitable for several industries and fields:

Organic fertilizer production: crush livestock manure, straw, etc., improve the fermentation effect, enhance the uniformity of organic fertilizer and nutrient absorption rate.

Biofertilizer manufacturing: Crush the microbial agent carrier material to the appropriate particle size to ensure the uniform distribution of microorganisms and improve fertilizer efficiency.

Agricultural waste treatment: crush straw, branches, husks, etc., and promote the resource utilization of organic waste.

Urban organic waste treatment: crush fruit peels, kitchen waste, etc., to achieve harmless treatment of organic waste.

IV’ Technical specifications

|

Power (kW) |

Capacity (t/h) |

Feed size (mm) |

Discharge particle size (mm) |

Applicable materials |

|

15 |

3-5 |

≤80 |

0.5-10 |

Manure, peels, kitchen waste |

|

22 |

5-8 |

≤100 |

0.5-8 |

Straw, husks, plant residues |

|

37 |

8-12 |

≤120 |

0.3-6 |

Livestock and poultry manure, garden waste |

|

55 |

10-20 |

≤150 |

0.3-5 |

Organic solid waste, fungus residue |

|

75 |

15-30 |

≤200 |

0.3-4 |

Large pieces of fruit and vegetable waste |

V’ Product features

1. Effective crushing capacity

The use of high-strength alloy blades or hammers can quickly process organic materials with high humidity, high fiber or high hardness, and greatly improve the crushing efficiency.

2. Wide range of applications

It is suitable for different types of organic wastes such as livestock and poultry manure, crop straw, fruit peel, kitchen waste, etc.

3. The particle size is adjustable

The screen of different specifications can be replaced to adjust the discharge particle size to meet different production needs.

4. Energy saving and environmental protection

The low-energy consumption motor is used to reduce energy consumption while operating efficiently, and is equipped with a dust removal device to reduce dust pollution.

5. The structure is sturdy and durable

The fuselage is made of thickened carbon steel, which is impact-resistant, wear-resistant, and has a long service life of the equipment.

6. Easy maintenance

Modular design, easy replacement of accessories, reduce maintenance costs, improve production continuity.

Organic fertilizer fragment machine is an important equipment on the organic fertilizer production line, which has the advantages of effective crushing, multi-functional application, energy saving and environmental protection, and easy maintenance, so that it is widely used in organic fertilizer, biological fertilizer and waste treatment industry.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Feb-19-2025