The design of the organic compost mixer focuses on structural rationality, ease of operation and high efficiency, so as to ensure adequate mixing and ventilation of the material during the composting process, while optimizing the composting efficiency and quality.

Here are the key design points of the compost mixer:

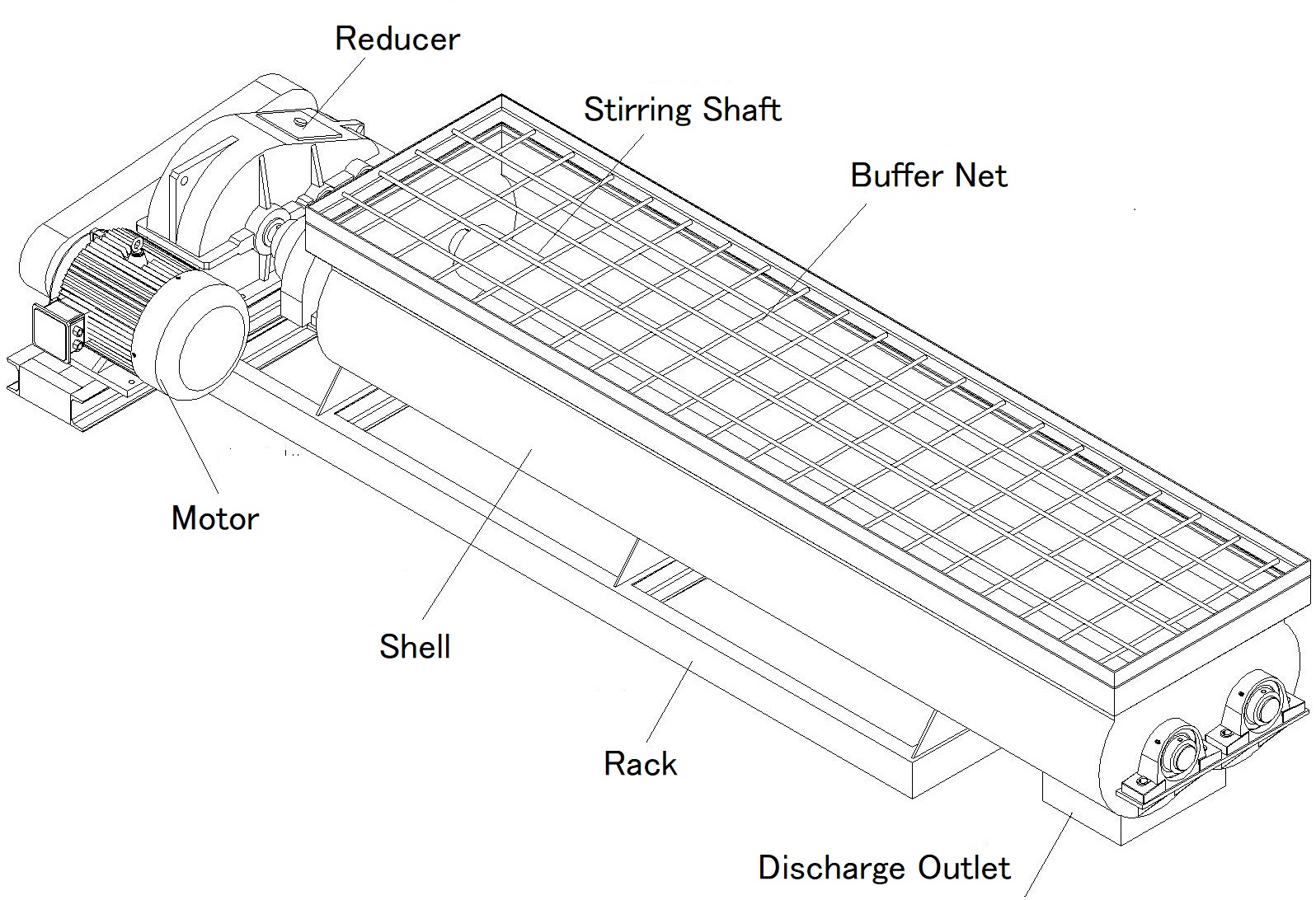

1. Overall structure

Main frame: high-strength steel is selected to ensure the stability and corrosion resistance of the equipment.

Blade system: Curved or spiral blades are designed for efficient turning and crushing of compost raw materials;

Blade material: wear-resistant and corrosion-resistant steel for extended life.

Drive system: Driven by motor or diesel engine, equipped with gear reduction system to ensure stable power output.

Conveyor system (optional): Combined with compost turning, the raw material is evenly distributed to the equipment operating area.

2. Functional design

Multi-directional stirring: longitudinal and transverse flip design is adopted to ensure that the material is evenly stirred.

Oxygen supplementation: Design vents or use forced ventilation systems to enhance aerobic fermentation in the composting process.

Humidity control sprinkler device: Equipped with an adjustable sprinkler system, it can evenly replenish water according to needs.

3. Dimensions and specifications

According to the site and processing capacity, we provide small and medium-sized (3-10 square meters) and large equipment (10-20 square meters/hour) design schemes, the common width is 2-3 meters, and the length is adjusted according to the application.

Mixing depth: generally 0.5-2 meters, can be customized according to needs.

4. Power and energy efficiency

Power: electric energy system or fuel system, the motor power is usually 22kW-75kW.

Reduced energy consumption: Frequency conversion technology can be added to adjust the stirring speed and power output.

5. Material and Maintenance

Construction material: stainless steel or corrosion-resistant alloy material to ensure corrosion resistance when in contact with organic materials for a long time.

Easy to clean design: the key components are easy to disassemble, easy to clean and maintain.

6. Combination of automation

Equipped with PLC intelligent control system to realize automatic operation and remote monitoring operation of equipment.

The induction system can monitor the temperature, humidity and other parameters of the material, and intelligently adjust the working mode.

Depending on the requirements, the organic compost mixer can also add more modules to the specific design, such as dust covers, mobile designs or linkage intelligent controls, to further optimize the performance of the equipment.

Mixing method: The organic compost mixer can adopt two ways: horizontal mixing and vertical mixing. The horizontal mixing mechanism is simple and suitable for large-area, thin-layer composting sites; Vertical mixers blend better, but the equipment is more complex.

Mixing speed and time: The setting of mixing speed and time should be determined according to the nature of the compost and the parameters of the blender to achieve the best mixing effect.

Mixing blades: Mixing blades are the key components of organic compost mixers, and their design should take into account factors such as the number of blades, shape, and materials to ensure the mixing effect and equipment life.

Equipment material: The organic compost mixer should be made of corrosion-resistant and wear-resistant materials to prolong the life of the equipment.

Safety: The design of the equipment should meet the relevant safety standards, and safety protection measures should be strengthened during use to avoid accidents.

In short, the design of the organic compost mixer should take into account the mixing effect, equipment life, safety, etc., to meet the production needs and use requirements.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Dec-24-2024