Fertilizer screening equipment is used for screening, grading, and sorting fertilizers. It is mainly applied to the inspection and adjustment of indicators such as particle size, moisture content, and impurities. Depending on the properties of the fertilizer and the production process, there are many types of fertilizer screening equipment, such as rotary drum screens and vibrating screens. Screening equipment can be combined as required to achieve more efficient production processes and better screening performance.

I. Product Overview

In modern chemical fertilizer and organic fertilizer production processes, fertilizer screening equipment is a key stage for ensuring product quality and uniformity of finished granules. With the increasing demand for precision fertilization in agriculture, the standardization of fertilizer particle size has become one of the important indicators for evaluating fertilizer grades. Fertilizer screening equipment is mainly used at the end of the production line to classify granulated materials, effectively separating qualified granules, oversized particles, and fine powder.

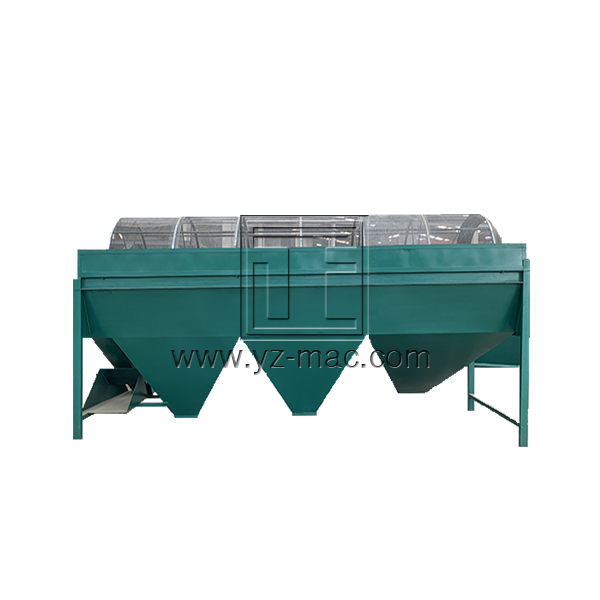

The screening equipment of Yizheng Heavy Industry incorporates advanced mechanical design concepts from both domestic and international sources and has been specially optimized for fertilizer materials (such as compound fertilizers, organic fertilizers, ammonium phosphate, etc.) that are prone to moisture absorption, caking, and corrosion. The equipment features a compact structure and stable operation, enabling long-term continuous performance in workshop environments with high dust and high humidity. According to different production capacity requirements and material characteristics, screening equipment can be classified into rotary drum screening machines, vibrating screening machines, and other types. It is an essential device for fertilizer manufacturers to achieve automated production and improve economic efficiency.

II. Working Principle

The core principle of fertilizer screening equipment is to utilize the relative motion between the material and the screening surface, allowing particles smaller than the screen aperture to pass through the screen, while particles larger than the aperture are retained on the screen surface, thereby achieving classification.

Taking the commonly used **rotary drum screening machine** as an example, its working principle is as follows:

The equipment consists of a cylindrical drum, frame, transmission system, and inlet and outlet ports. The drum is installed at an incline on the frame, and the motor drives the drum to rotate around its axis through a reducer. When fertilizer material enters the rotating drum, it is lifted along the drum wall under the combined effects of centrifugal force and friction. After reaching a certain height, the material falls due to gravity. During the continuous tumbling and sliding process, fine material is discharged through the screen installed on the drum body, while coarse material moves forward along the inclination of the drum and is finally discharged from the coarse outlet at the rear end.

For the **vibrating screening machine**, the excitation force generated by the vibration motor causes the screen body to perform periodic reciprocating motion in a specified direction. The material moves forward on the screen surface in a jumping manner. During this process, material smaller than the screen aperture falls to the lower layer, thereby achieving multi-level classification. To prevent fertilizer from clogging the screen apertures, the equipment is usually equipped with automatic cleaning devices (such as bouncing balls or cleaning brushes) to ensure screening efficiency.

III. Product Applications

Fertilizer screening equipment is widely used in various fertilizer production fields, covering the entire industry chain from chemical fertilizers to biological fertilizers:

* Compound fertilizer production lines: After granulation and drying, products are strictly graded. Standard granules that meet market specifications are selected, oversized particles are returned to the crusher, and fine powder is returned to the granulator for secondary processing.

* Organic fertilizer and bio-organic fertilizer production: Organic fertilizer raw materials are complex in composition. Screening equipment can effectively remove coarse fibers or impurities that have not been fully fermented, improving the visual appearance and commercial value of the finished product.

* Bulk blending (BB fertilizer) pre-processing: Before BB fertilizer blending, base fertilizers are screened to ensure uniform particle size of each component, preventing secondary segregation during transportation and application.

* Phosphate fertilizer and urea production: Used as the final process before packaging to remove fines and agglomerates, ensuring that each bag of fertilizer delivered to farmers has good flowability.

IV. Product Features

Designed specifically for the special production environment of the fertilizer industry, fertilizer screening equipment offers the following significant advantages:

* High efficiency and precise classification: Optimized screen angles and rotational speeds ensure even material distribution on the screen surface, high screening efficiency, and precise control of finished fertilizer particle size distribution.

* Anti-clogging structural design: In response to the moisture-sensitive and adhesive nature of fertilizers, the equipment is equipped with efficient screen-cleaning mechanisms, effectively solving the problem of screen apertures being blocked by embedded materials and reducing downtime for maintenance.

* Strong corrosion resistance and durability: Considering the strong corrosiveness of fertilizers (such as chloride-based fertilizers and acidic materials), material-contact parts can be made of high-quality stainless steel or treated with special anti-corrosion coatings, significantly extending equipment service life.

* Low noise and environmentally sealed design: The equipment adopts a fully enclosed structure to effectively prevent dust leakage and improve the workshop working environment. The transmission system is precisely balanced, with operating noise levels below national standards, meeting green production requirements.

* Convenient maintenance and simple operation: The modular design allows for easy screen replacement, enabling quick changes of screen apertures according to different order requirements. The simple structure allows operators to use the equipment with only basic training.

In summary, this fertilizer screening equipment, with its outstanding stability and specialized design, effectively addresses the core challenges in fertilizer production—namely incomplete screening, frequent screen clogging, and corrosion—and is an ideal choice for fertilizer enterprises seeking to optimize product quality and reduce production costs.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Jan-12-2026