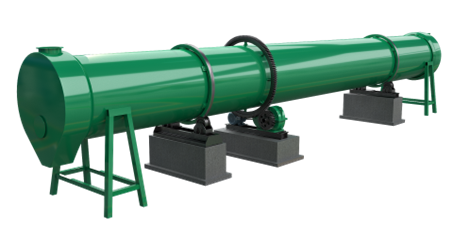

Organic Fertilizer Dryer is a large-scale machine used to dry formed fertilizer granules and is one of the key pieces of equipment in the fertilizer industry. The machine uses a fan installed at the tail to continuously draw hot air generated by the furnace at the head through the drum. As the drum rotates, lifting plates inside continuously raise and drop the granules, allowing them to fully contact the hot air, removing moisture and achieving uniform drying.

This dryer can reduce the moisture content of livestock and poultry manure from 30%–50% down to a safe level for storage in one cycle. The rotary drum dryer features a slightly inclined rotating cylinder. Materials are fed into the hopper at the upper end by a belt or bucket conveyor, and the dried product is discharged through the outlet at the tail. The entire drying process is carried out in a sealed system, minimizing environmental pollution. Materials with high moisture content are evenly distributed and agitated inside the drum by lifting plates, ensuring full contact with hot air to accelerate the drying process. Rotary dryers have high capacity, can operate continuously, and offer smooth, stable material movement. They also feature wide applicability and ensure uniform product drying. The dried granules are easier to pack, store, and transport while enhancing product stability and shelf life.

I. Working Principle:

The organic fertilizer dryer typically adopts a rotary drum drying structure:

1.Material is fed into the drum through a conveyor.

2.The drum slowly rotates, driven by a main motor, with lifting plates inside raising and scattering the material.

3.Hot air generated by the furnace enters from one end and contacts the material either in co-current or counter-current flow.

4.Moisture is rapidly evaporated through heat conduction and convection.

5.Dried material is discharged from the outlet and is cooled, screened, and packed.

II. Main Technical Parameters:

|

Model Specification |

Diameter (mm) |

Length (mm)) |

Overall Dimensions After Installation (mm) |

Rotational Speed (r/min) |

Motor Model |

Power (kw) |

|

YZHG-0880 |

800 |

8000 |

9000×1700×2400 |

6 |

Y132S-4 |

5.5 |

|

YZHG-10100 |

1000 |

10000 |

11000×1600×2700 |

5 |

Y132M-4 |

7.5 |

|

YZHG-12120 |

1200 |

12000 |

13000×2900×3000 |

4.5 |

Y132M-4 |

7.5 |

|

YZHG-15150 |

1500 |

15000 |

16500×3400×3500 |

4.5 |

Y160L-4 |

15 |

|

YZHG-18180 |

1800 |

18000 |

19600×3300×4000 |

4.5 |

Y225M-6 |

30 |

|

YZHG-20200 |

2000 |

20000 |

21600×3650×4400 |

4.3 |

Y250M-6 |

37 |

|

YZHG-22220 |

2200 |

22000 |

23800×3800×4800 |

4 |

Y250M-6 |

3 |

|

YZHG-24240 |

2400 |

24000 |

26000×4000×5200 |

4 |

Y280S-6 |

45 |

Note: Large-scale models can be custom-designed based on actual production needs.

III. Applicable Materials:

- Fermented livestock and poultry manure (chicken, pig, cow, etc.)

- Decomposed kitchen waste, municipal sludge

- Distiller’s grains, sugar mill filter mud, crop straw powder

- Moist organic fertilizer granules

- Post-granulation drying section in organic fertilizer production lines

IV. Product Advantages:

1.High-Efficiency Drying : Multiple lifting plate configurations ensure full heat contact, enabling fast and efficient drying.

2.Energy-Saving & Eco-Friendly : Compatible with biomass pellets, straw, natural gas, and other heat sources with low energy consumption.

3.Stable Operation : Adjustable rotation speed and material flow; integrated intelligent temperature control system ensures continuous and reliable performance.

4.Durable Structure : Drum made from Q345 manganese steel or stainless steel; corrosion-resistant and wear-resistant, suitable for long-term high-temperature use.

5.Flexible Integration : Easily connects with granulators, coolers, screeners, and other equipment to achieve automated production.

V. Price Reference:

|

Capacity Range |

Price Range (CNY) |

Notes |

|

Small (1–2 tons/hour) |

¥80,000 ~ ¥120,000 |

Single drum with standard blower + dust removal system. |

|

Medium (3–5 tons/hour) |

¥130,000 ~ ¥180,000 |

Includes hot air furnace, cyclone dust collector. |

|

Large (6–10 tons/hour) |

¥200,000 ~ ¥320,000+ |

Optional PLC control and custom heat source solutions. |

Optional configurations: automatic feeding, cooling system, cyclone dust collector, wet scrubber, combustion furnace, PLC automatic control, etc.

VI. Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd.

- Specialized in organic fertilizer equipment for over 20 years, providing complete solutions for drying, granulating, mixing, crushing, and packaging.

- Dryers can be customized for diameter, length, and heat source types.

- Full line engineering design, on-site installation, commissioning, and operation training provided.

- Official Website: www.yz-mac.com / www.yz-mac.cn

VII. Purchasing Tips:

Before purchasing an organic fertilizer dryer, please confirm the following:

1.Required daily/hourly output (e.g., 5 tons/hour?)

2.Initial moisture content and target final moisture (e.g., ≤15%?)

3.Material characteristics (powder? granules? sticky or corrosive?)

4.Existing heat source setup (coal, gas, biomass, etc.)

5.Whether integration with granulating, screening, and packaging equipment is needed

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Aug-07-2025