A continuous dryer is a type of drying equipment capable of uninterrupted operation, making it ideal for large-scale industrial production lines.

Its working principle involves conveying wet materials into a drying chamber via a transport system, where hot air is applied to remove moisture. The dried products are then discharged through the outlet. This type of dryer features continuous operation, a high level of automation, and high production efficiency, and is widely used in industries such as food processing, chemical manufacturing, pharmaceuticals, and building materials for drying and baking processes.

I. Basic Principle :

Continuous dryers generally adopt either a **Rotary Drum** or **Conveyor Belt** structure. Raw materials enter from one end, come into full contact with hot air inside the drum or on the belt, and gradually release moisture. The finished product is discharged from the other end, achieving a fully continuous process.

II. Common Types :

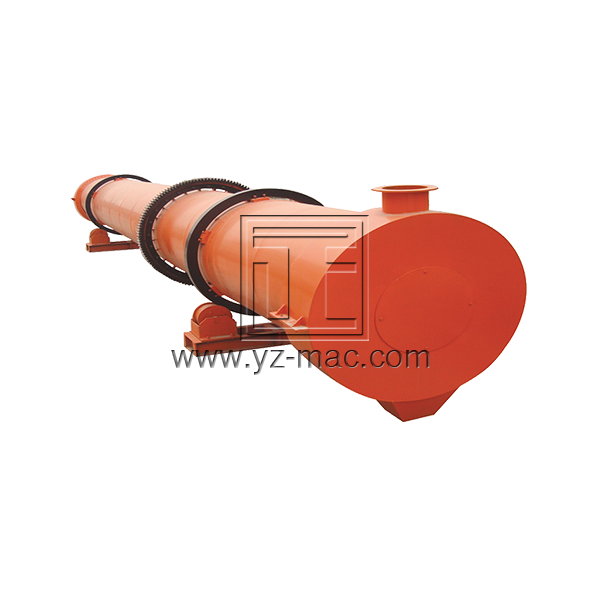

**Rotary Drum Continuous Dryer**

- The internal drum rotates slowly, causing the raw materials to tumble and stir, ensuring thorough contact with hot air.

- Suitable for granular organic fertilizers, compound fertilizers, and pelletized chemical fertilizers.

- Features large processing capacity and high durability.

**Conveyor Belt Continuous Dryer**

- Raw materials are evenly layered on a mesh belt, with hot air passing from above or below for drying.

- Ideal for delicate or irregularly shaped fertilizers.

- Provides uniform drying but requires a larger footprint.

III. Advantages :

- Continuous Operation: Suitable for high-output production lines, reducing downtime.

- Uniform Drying: Ensures even heat exposure, minimizing clumping risks.

- High Automation: Can be integrated with coolers, screening machines, and packing machines to form automated production lines.

- High Efficiency: Delivers high thermal utilization with controlled operating costs.

IV. Supporting Equipment :

To achieve optimal performance, continuous dryers are typically paired with:

- Continuous Cooler (Rotary Drum Cooler): Lowers product temperature to prevent moisture rebound.

- Dust Removal System: Reduces dust emissions during drying.

- Heat Source System: Such as gas furnaces, steam boilers, or biomass burners.

V. Selection Recommendations :

- Capacity Requiremen: Define hourly throughput (e.g., 5–30 tons/hour).

- Fertilizer Type: Organic fertilizers require lower drying temperatures, while compound fertilizers can withstand higher drying temperatures.

- Energy Efficiency & Environmental Compliance: Select designs with high thermal efficiency and equipped with dust filtration systems.

- Material Durability: Prefer corrosion-resistant steel (e.g., 304 stainless steel) for all fertilizer-contact components.

For more inquiries or more information, please contact:

Sales Department / Tina Tian

+86 – 15538237222

Zhengzhou Yizheng Heavy Machinery Equipment Co., Ltd

Email: tianyaqiong@yz-mac.cn

Website: www.yz-mac.com

Post time: Oct-03-2025