I. Product Overview:

Organic Fertilizer Drying Equipment is specialized machinery used to dehydrate and dry molded or semi-molded organic fertilizers (such as granular or powdered forms). Its core purpose is to reduce the moisture content of the finished product, thereby enhancing the fertilizer’s stability, storability, and commercial value.

This equipment is widely used in agriculture, horticulture, and livestock farming, and can process various types of organic fertilizers, such as livestock and poultry manure, kitchen waste, and crop straw. Dried organic fertilizers not only have a longer shelf life and greater stability but are also easier to store and transport.

Common types include rotary drum dryers, airflow dryers, and belt dryers. Among them, the rotary drum dryer is the most widely used in the industry due to its large processing capacity and broad applicability to different materials.

Organic fertilizer drying equipment works by heating and evaporating the water content in the fertilizer, thereby improving its quality and stability.

II. Working Principle:

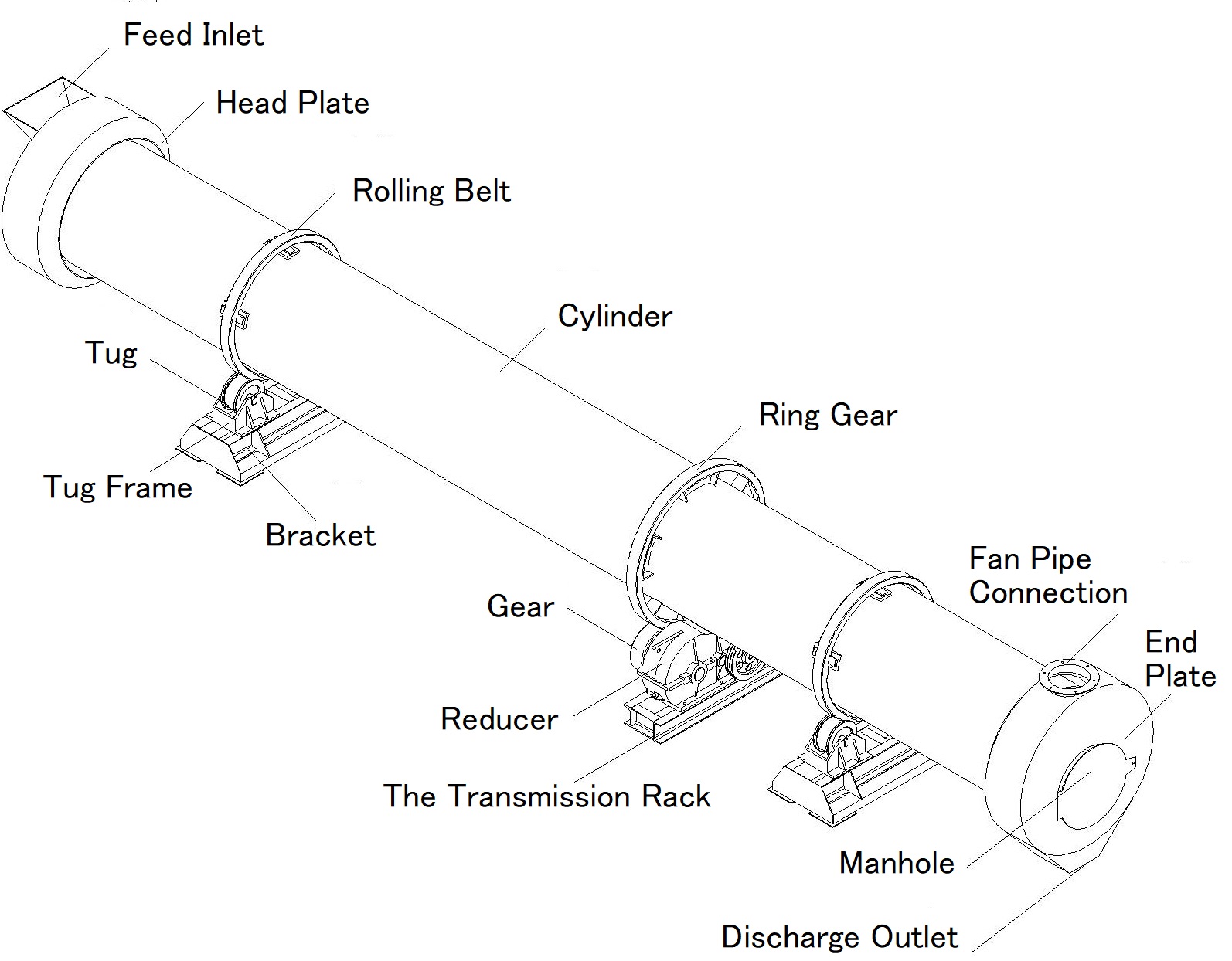

Using a rotary drum dryer as an example, the main workflow is as follows:

1. Feeding – Materials are conveyed into the rotating drum via a feeding device.

2. Hot Air Drying – High-temperature airflow (usually 300–800°C) generated by a furnace or hot air stove flows along the drum’s interior wall and contacts the material. Heat convection and conduction quickly evaporate moisture from the material.

3. Rolling & Lifting – The drum rotates at low speed, and lifter plates continuously scatter the material, ensuring full contact with hot air for uniform drying.

4. Discharging – Once the target moisture level is reached, materials are discharged via the outlet and enter cooling equipment or are directly packaged.

III. Product Applications:

*Agricultural Waste – Straw powder, organic residues, mushroom waste, etc.

*Livestock & Poultry Manure Fertilizer – Fermented chicken manure, cow manure, pig manure pellets.

*Organic/Inorganic Compound Fertilizers – Post-granulation drying.

*Municipal Organic Waste – Kitchen waste fertilizer, garden waste fertilizer, etc.

VI. Product Features:

*High Energy Efficiency – Uses counterflow or parallel flow drying methods for high thermal efficiency and low fuel consumption.

*Wide Applicability – Suitable for multiple material forms (granules, powder, flakes) and varying moisture levels.

*Uniform Drying – Optimized lifter plate design prevents material clumping and incomplete drying.

*High Automation – Can be equipped with automatic temperature control, humidity detection, and PLC control systems for continuous operation.

*Strong Durability– Drum body made of wear-resistant steel plates; optional heat-resistant and corrosion-resistant lining for extended service life.

Main technical parameter:

|

Model |

Diameter (mm) | Length (mm) | Installed Dimensions (mm) | Speed (r/min) | Motor type | Power (kw) |

|

YZHG-0880 |

800 | 8000 | 9000×1700×2400 | 6 | Y132S-4 | 5.5 |

|

YZHG-10100 |

1000 | 10000 | 11000×1600×2700 | 5 | Y132M-4 | 7.5 |

|

YZHG-12120 |

1200 | 12000 | 13000×2900×3000 | 4.5 | Y132M-4 | 7.5 |

|

YZHG-15150 |

1500 | 15000 | 16500×3400×3500 | 4.5 | Y160L-4 | 15 |

|

YZHG-18180 |

1800 | 18000 | 19600×3300×4000 | 4.5 | Y225M-6 | 30 |

|

YZHG-20200 |

2000 | 20000 | 21600×3650×4400 | 4.3 | Y250M-6 | 37 |

|

YZHG-22220 |

2200 | 22000 | 23800×3800×4800 | 4 | Y250M-6 | 37 |

|

YZHG-24240 |

2400 | 24000 | 26000×4000×5200 | 4 | Y280S-6 | 45 |

Pricing & Models:

The price and model of organic fertilizer drying equipment vary depending on brand, model, specifications, and manufacturing process. Selection should be based on specific production requirements. Generally, prices range from several thousand to hundreds of thousands of RMB.

For more inquiries or more information, please contact:

Post time: Aug-14-2025