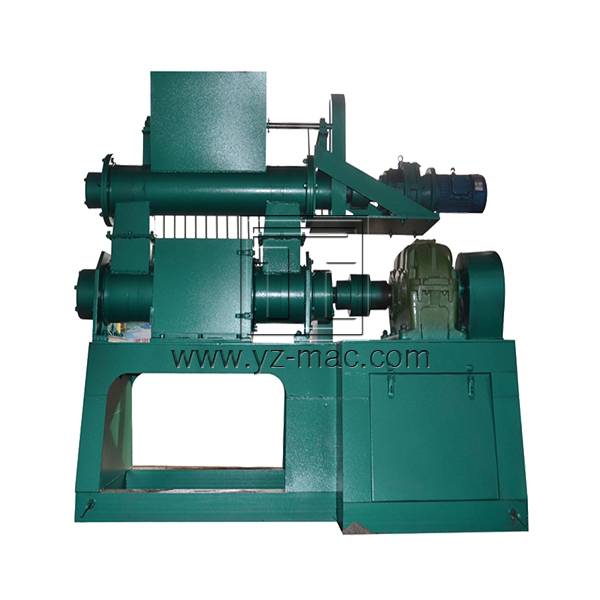

New Arrival China Compost Turner Tractor - Double Screw Composting Turner – YiZheng

New Arrival China Compost Turner Tractor - Double Screw Composting Turner – YiZheng Detail:

The new generation of Double Screw Composting Turner Machine improved double axis reverse rotation movement, so it has the function of turning, mixing and oxygenation, improving the fermentation rate, decomposing quickly, preventing the formation of the odor, saving the energy consumption of oxygen filling, and shortening the fermentation time. The turning depth of this equipment can reach up to 1.7 meters and the effective turning span can reach 6-11 meters.

(1) Double Screw Composting Turner Machine is widely used in fermentation and water removal operations such as organic fertilizer plants, compound fertilizer plants,

(2) Especially suitable for the fermentation of low organic materials such as sludge and municipal waste (because of the low organic content, a certain fermentation depth must be given to improve the fermentation temperature, thus reducing the fermentation time).

(3) Make sufficient contact between materials and oxygen in the air, so as to play the important role of aerobic fermentation.

1. Regulation of carbon-nitrogen ratio (C/N). The suitable C/N for decomposition of organic matter by general microorganisms is about 25:1.

2. Water control. The water content of compost in actual production is generally controlled at 50%-65%.

3. Compost ventilation control. Oxygen supply is an important factor for the success of compost. It is generally believed that oxygen in the pile is suitable for 8% ~ 18%.

4. Temperature control. Temperature is an important factor affecting the activity of microorganisms of compost. The fermentation high temperature is usually between 50-65°C.

5. PH control. PH is an important factor affecting the growth of microorganisms. The best PH should be 6-9.

6. Smelly control. At present, more microorganisms are used to deodorize.

(1) The fermentation groove that can realize the function of one machine with multiple grooves can be discharged continuously or in batches.

(2) High fermentation efficiency, stable operation, strong and durable, uniform turning.

(3) Suitable for aerobic fermentation can be used in conjunction with solar fermentation chambers and shifters.

|

Model |

Main Motor |

Moving Motor |

Walking Motor |

Hydraulic Pump Motor |

Groove Depth |

|

L×6m |

15kw |

1.5kw×12 |

1.1kw×2 |

4kw |

1-1.7m |

|

L×9m |

15kw |

1.5kw×12 |

1.1kw×2 |

4kw |

|

|

L×12m |

15kw |

1.5kw×12 |

1.1kw×2 |

4kw |

|

|

L×15m |

15kw |

1.5kw×12 |

1.1kw×2 |

4kw |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Complete production equipment for organic fertilizer

6. Dryer equipment: tumble dryer. New Arrival China Compost Turner Tractor - Double Screw Composting Turner – YiZheng , The product will supply to all over the world, such as: San Francisco, Philippines, Costa rica, Granular fertilizer making machine

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.