Manure processing machine

A manure processing machine, also known as a manure processor or manure management system, is a specialized equipment designed to handle and process animal manure effectively. It plays a crucial role in agricultural operations, livestock farms, and waste management facilities by converting manure into valuable resources while minimizing environmental impact.

Benefits of Manure Processing Machines:

Waste Reduction and Environmental Protection: Manure processing machines help reduce the volume of animal manure, minimizing storage and disposal requirements. By processing and treating manure properly, these machines help prevent environmental pollution and contamination of water sources, protecting ecosystems and promoting sustainable waste management practices.

Nutrient Recovery and Resource Utilization: Manure contains valuable nutrients, such as nitrogen, phosphorus, and potassium, which can be recycled and utilized as organic fertilizer. Manure processing machines separate solids from liquids, allowing for the extraction of nutrient-rich solids for composting or pelletizing. The resulting organic fertilizer can be used to improve soil fertility and support crop growth, reducing the need for synthetic fertilizers.

Odor Mitigation: Proper processing of manure significantly reduces the release of odorous gases associated with raw manure. Manure processing machines employ techniques like composting, drying, or anaerobic digestion, which help break down organic matter, reduce odors, and create a more manageable and odor-free end product.

Energy Generation: Some manure processing machines, particularly those employing anaerobic digestion, can generate biogas as a byproduct. Biogas, primarily composed of methane, can be captured and utilized as a renewable energy source for heat and electricity generation, reducing reliance on fossil fuels and promoting sustainable energy production.

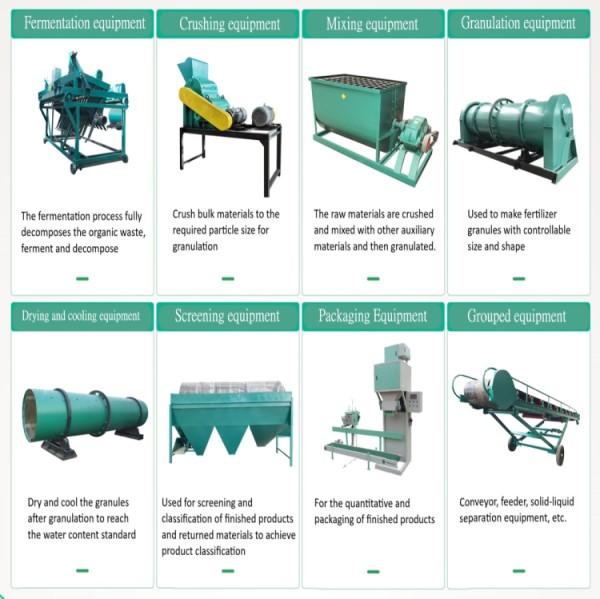

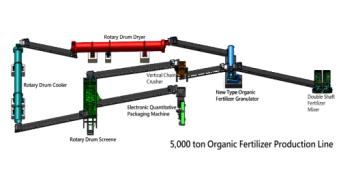

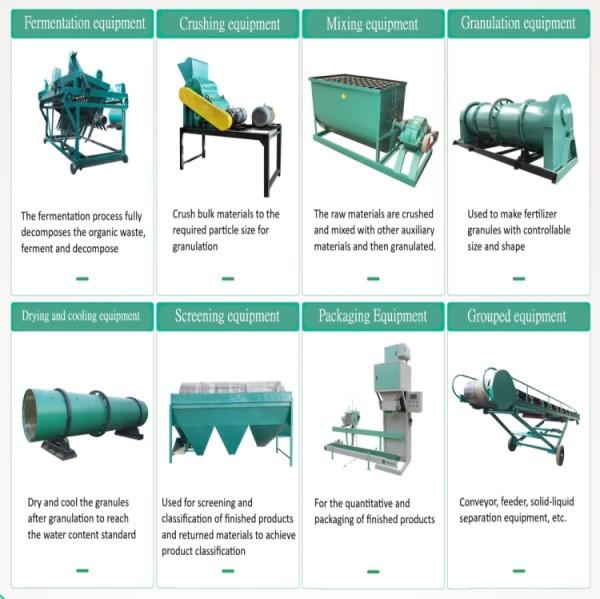

Working Principles of Manure Processing Machines:

Manure processing machines employ various techniques based on the desired outcome and available resources. These techniques include:

Composting: Composting involves the controlled decomposition of manure in the presence of oxygen. Manure is mixed with carbon-rich materials and allowed to undergo aerobic decomposition, resulting in stabilized organic matter that can be used as compost.

Drying: Drying involves reducing the moisture content of manure, making it more manageable for storage, transportation, and further processing. This process helps kill pathogens and reduces odor.

Anaerobic Digestion: Anaerobic digestion is a biological process that occurs in the absence of oxygen. Manure is broken down by anaerobic bacteria, producing biogas and digestate. Biogas can be used as an energy source, while digestate can be further processed into nutrient-rich fertilizer.

Applications of Manure Processing Machines:

Agriculture and Crop Production: Manure processing machines are widely used in agriculture to convert animal manure into organic fertilizer. This fertilizer can be applied to fields to improve soil fertility, promote plant growth, and reduce reliance on synthetic fertilizers.

Livestock Farms: Manure processing machines play a crucial role on livestock farms, where large volumes of manure are generated. They help manage manure more efficiently, reduce odor, and prevent nutrient runoff, ensuring compliance with environmental regulations and enhancing overall farm sustainability.

Biogas Production Facilities: Manure processing machines employing anaerobic digestion are used in biogas production facilities. They convert manure into biogas, which can be utilized for heat and electricity generation, providing renewable energy and reducing greenhouse gas emissions.

Waste Management Facilities: Manure processing machines are employed in dedicated waste management facilities that handle organic waste from various sources. These facilities process manure to minimize environmental impact, recover nutrients, and produce value-added products like organic fertilizer or biogas.

Manure processing machines are essential tools in the efficient management of organic waste, particularly animal manure. They offer numerous benefits, including waste reduction, nutrient recovery, odor mitigation, and energy generation. Through techniques such as composting, drying, or anaerobic digestion, these machines transform manure into valuable resources like organic fertilizer or renewable energy. The applications of manure processing machines span across agriculture, livestock farms, biogas production facilities, and waste management facilities, contributing to sustainable waste management practices and environmental protection.