Manufacturer for Masterbatch Dryers - Vertical Disc Mixing Feeder Machine – YiZheng

Manufacturer for Masterbatch Dryers - Vertical Disc Mixing Feeder Machine – YiZheng Detail:

The Vertical Disc Mixing Feeder Machine is also called disc feeder. The discharge port can be controlled flexible and the discharge quantity can be adjusted according to the actual production demand. In the compound fertilizer production line, the Vertical Disc Mixing Feeder Machine is often used in combination with several roller extrusion granulators to provide even material feeding, that greatly improving the feeding efficiency and production capacity

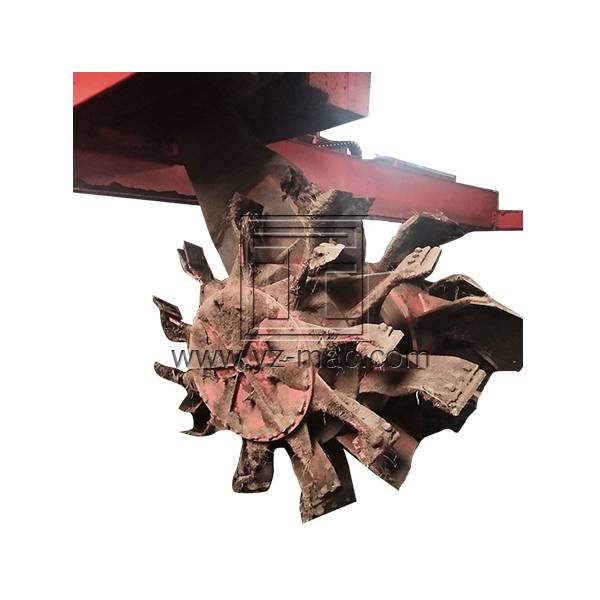

This machine is a new vertical disc mixing feeder, which consists of mixing plate, discharge port, mixing arm, rack, gearbox and transmission mechanism. We adopt special wearing alloy for the spiral blade for longer service time. The disc mixing feeder feeds from the top and discharge from the bottom with reasonable structure. The characteristic of the machine is that the output shaft end of the reducer drives the stirring main shaft to operate, and the stirring shaft has fixed stirring teeth, so the stirring shaft drives the stirring teeth to mixing the material sufficiently and makes the material flow out evenly. The discharge port can be opened according to needs to control the flow of materials to ensure the smooth production of the whole process.

It is a new type mixing & feeding equipment for continuous running. It is mainly used in the fertilizer processing industry, and we supply the turn-key basis fertilizer project start from design, producing, installation, debugging and technical training. It can also be used in chemical, metallurgy, mining, building materials and other industries.

(1) The Vertical Disc Mixing Feeder Machine has long service life, energy saving, small volume, fast stirring speed and continuous working.

(2) The inside of the disc can be lined with polypropylene plate or stainless steel plate. It is not easy to stick material and wear resistance.

(3) The cycloid pinwheel reducer makes the machine has the characteristics of compact structure, convenient operation, uniform feeding, and convenient discharge and transportation.

(4) The Vertical Disc Mixing Feeder Machine feeds the material from top, discharge from bottom, which is reasonable.

(5) The sealing between each combination surface is tight, so the machine runs smoothly.

|

Model |

Disc Diameter (mm) |

Edge Height (mm) |

Speed (r/min) |

Power (kw) |

Dimensions (mm) |

Weight (kg) |

|

YZPWL1600 |

1600 |

250 |

12 |

5.5 |

1612×1612×968 |

1100 |

|

YZPWL1800 |

1800 |

300 |

10.5 |

7.5 |

1900×1812×968 |

1200 |

|

YZPWL2200 |

2200 |

350 |

10.5 |

11 |

2300×2216×1103 |

1568 |

|

YZPWL2500 |

2500 |

400 |

9 |

11 |

2600×2516×1253 |

1950 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

compost turner machine Manufacturer for Masterbatch Dryers - Vertical Disc Mixing Feeder Machine – YiZheng , The product will supply to all over the world, such as: Surabaya, Georgia, United Arab Emirates, The fertilizer mixer is an essential and important equipment in the biological fermentation tank. Different slurry type mixers are selected in the biological fermentation tank to make each area in the tank meet the requirements of gas-liquid dispersion, solid-liquid suspension, mixing, heat transfer, etc. Fermentation yield, reduce energy consumption.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.