Low price for Npk Fertilizer Production Process - Cow manure organic fertilizer fermentation equipment manufacturer – YiZheng

Low price for Npk Fertilizer Production Process - Cow manure organic fertilizer fermentation equipment manufacturer – YiZheng Detail:

Cow manure organic fertilizer fermentation equipment.

Yizheng Heavy Industry is a professional manufacturer of organic fertilizer equipment. It provides a complete set of fertilizer production line equipment such as pile turning machine, grinder, granulator, rounding machine, screening machine, dryer, cooling machine, packaging machine and so on.

The walking stacker, double spiral stacker, trough tiller, trough hydraulic stacker, crawler type stacker, horizontal fermentation tank, roulette stacker, forklift tipper produced by our company Customers of different stackers, such as stackers, can choose according to the actual composting raw materials, sites and products.

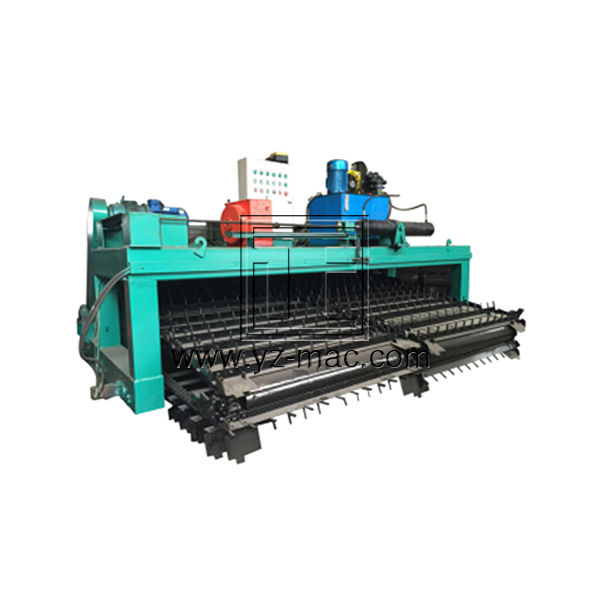

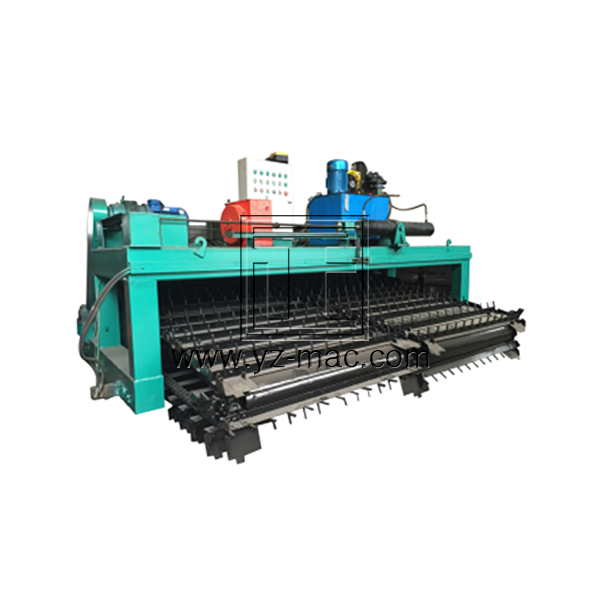

The walking system of the chain-plate type stacker on the fermentation tank adopts frequency conversion speed regulation, which has good adaptability to different materials, stable and high-efficiency stacking. It is a stacker that shortens the fermentation period and increases production. The chain-plate type stacker is used for livestock Trough oxygen-consuming composting of organic solid wastes such as poultry manure and sludge garbage.

Chain Plate Composting Turner Machine Model Selection:

|

No. |

Parameter Name |

Unit |

Model |

||

|

YZFJLB-30 |

YZFJLB-40 |

YZFJLB-50 |

|||

|

1 |

Power |

kw |

19 |

20.5 |

30 |

|

2 |

Chain plate width |

mm |

3000 |

4000 |

5000 |

|

3 |

Speed of work |

m/h |

Adjustable |

Adjustable |

Adjustable |

|

4 |

No-load Speed |

m/h |

Adjustable |

Adjustable |

Adjustable |

|

5 |

Width of the fermentation tank |

mm |

3380 |

4380 |

5380 |

|

6 |

Height of the fermentation tank |

mm |

1500 |

1500 |

2000 |

|

7 |

Material height |

mm |

1300 |

1300 |

1800 |

|

8 |

Maximum turning ability |

m³/h |

|

|

|

|

9 |

Material displacement of each turning |

m |

4 |

4 |

4.5 |

|

10 |

Maximum lifting height |

m |

2.5 |

2.5 |

3.4 |

For more detailed solutions or products, please pay attention to our official website:

https://www.yz-mac.com/chain-plate-compost-turning-2-product/

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Compound fertilizer production process

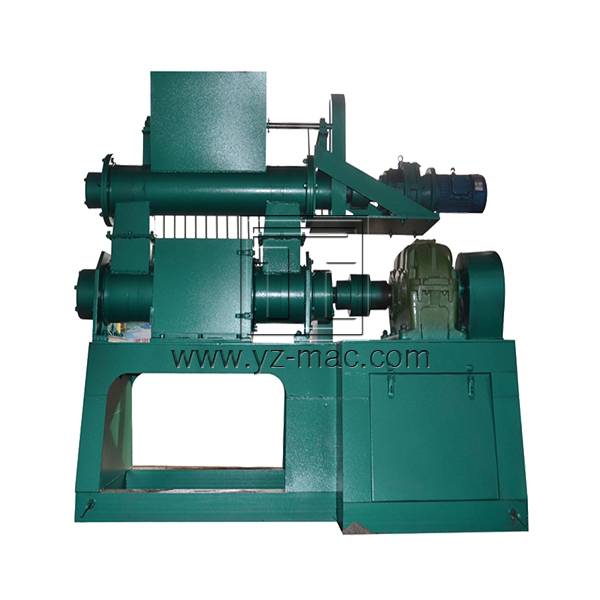

During the composting process, the heap should be turned if necessary. Generally, it is carried out when the heap temperature crosses the peak and begins to cool down. The heap turner can re-mix the materials with different decomposition temperatures of the inner layer and the outer layer. If the humidity is insufficient, some water can be added to promote the compost to decompose evenly. Low price for Npk Fertilizer Production Process - Cow manure organic fertilizer fermentation equipment manufacturer – YiZheng , The product will supply to all over the world, such as: Provence, Kazakhstan, Auckland, Extrusion granulator belongs to dry granulation, no drying process, high granulation density, good fertilizer efficiency, and full organic matter content

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.