High reputation Disc-Ball Granulator - New Type Organic Fertilizer Granulator – YiZheng

High reputation Disc-Ball Granulator - New Type Organic Fertilizer Granulator – YiZheng Detail:

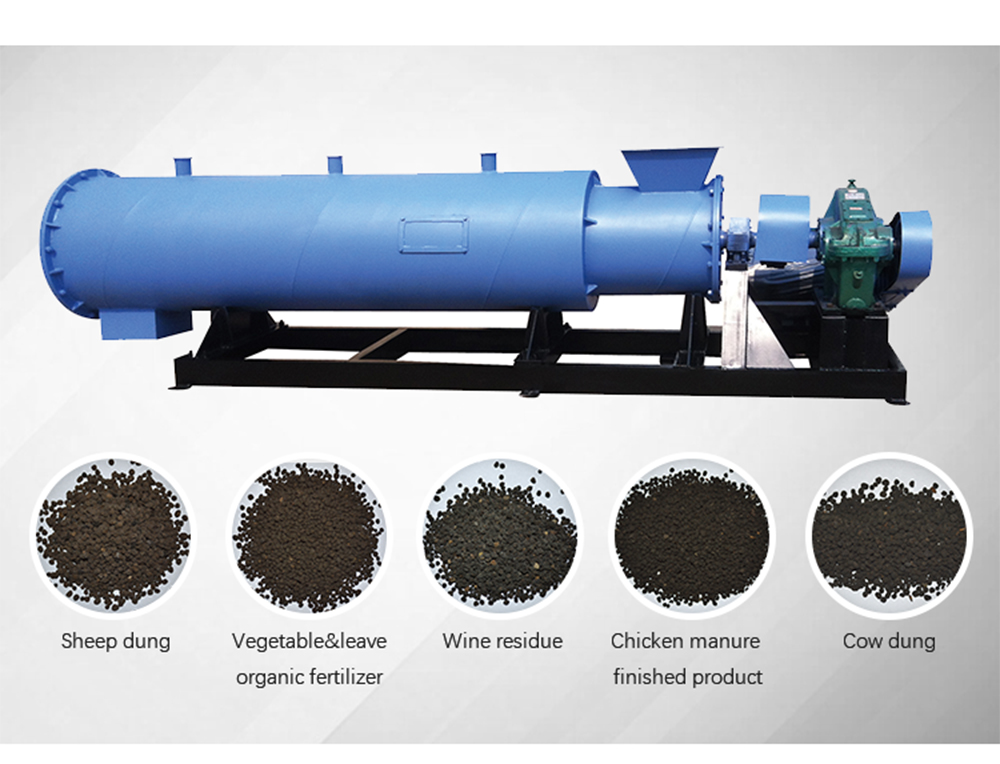

New Type Organic Fertilizer Granulator is widely used in granulation of organic fertilizer. A new type of organic fertilizer granulator, also known as wet agitation granulation machine and internal agitation granulation machine, is the latest new organic fertilizer granulator developed by our company. The machine can not only granulate a variety of organic matter, especially for the coarse fiber materials which are difficult to be granulated by conventional equipment, such as crop straw, wine residue, mushroom residue, drug residue, animal dung and so on. The granulation can be made after fermentation, and it also can be achieved the better effect of grain making to acid and municipal sludge.

Commercial Organic Fertilizers:

a) Industrial waste: such as distiller’s grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.

b) Municipal sludge: such as river sludge, sewer sludge, etc. Organic fertilizer raw material production and supply base classification: silkworm sand, mushroom residue, kelp residue, phosphocitric acid residue, cassava residue, protein mud, glucuronide residue, amino acid humic acid, oil residue, grass ash, shell powder, concurrently operating, peanut shell powder, etc.

Bio-Organic Fertilizer:

a) Agricultural waste: such as straw, soybean meal, cotton meal, etc.

b) Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

c) Household garbage: such as kitchen garbage;

The new type organic fertilizer granulator uses the mechanical stirring force of high-speed rotation and the aerodynamics resulting from it to continuously mix, granulate, spherical, dense and other processes of fine powder in the machine, so as to achieve granulation. The particle shape is spherical, the particle size is generally between 1.5 and 4 mm, and the particle size of 2~4.5mm is ≥90%. The particle diameter can be appropriately adjusted by material mixing and spindle speed. Usually, the lower the mixing amount, the higher the rotation speed, the smaller the particle, and the larger the particle.

►The product granule is round ball.

►The organic content can be high to 100%, make pure organic granulate.

►Organic material particles can grow up under a certain force, no need to add binder. when granulating.

►Product granule is massy, it can sieve directly after granulation to reduce the energy. consumption of drying.

►After fermentation organics don’t need to dry, moisture of the raw material can be in. 20%-40%.

In order to meet the needs of the large-scale organic fertilizers, WE Zhengzhou Yizheng Heavy Machinery Co., Ltd. professionally design and manufacture the organic fertilizer production line and relevant machines fitting for the different organic materials, which has been the leader in the field in China.

|

Annual Output of Small-Sized Organic Fertilizer Plant (300 Working Days) |

|||||

|

10,000 tons/ year |

20,000 tons/ year |

30,000 tons/ year |

|||

|

1.4 tons/ hour |

2.8 tons/ hour |

4.2 tons/ hour |

|||

|

Annual Output of Medium-Sized Organic Fertilizer Plant |

|||||

| 50,000 tons/ year | 60,000 tons/ year | 70,000 tons/ year | 80,000 tons/ year | 90,000 tons/ year | 100,000 tons/ year |

| 6.9 tons/ hour | 8.3 tons/ hour | 9.7 tons/ hour | 11 tons/ hour | 12.5 tons/ hour | 13.8 tons/ hour |

|

Annual Output of Large-Sized Organic Fertilizer Plant |

|||||

| 150,000 tons/ year | 200,000 tons/ year | 250,000 tons/ year | 300,000 tons/ year | ||

| 20.8 tons/ hour | 27.7 tons/ hour | 34.7 tons/ hour | 41.6 tons/ hour | ||

Free from seasonal restrictions and low overhead costs Aerobic fermentation

“Turn waste into treasure”, no foul treatment, harmless treatment

Short production cycle of organic fertilizer

Simple operation and convenient management

- Fermentation Process:

Fermentation is the basic process of production. Moisture, temperature and time need to be strictly controlled. Compost turner is the organic fertilizer machine used to accelerate the fermentation of micro-organisms and improve the quality of compost.

- Crushing Process:

Lump materials should be crushed after the fermentation process. It is difficult to make the matter into granules manually. In this way, it is necessary to use fertilizer crusher. We recommend customers choose high moisture materials crusher machine, as it can crush semi-wet material and with high crushing efficiency.

- Granulating Process:

It is the important production process in the whole production line. According to different requirements, nutrients can be added. Spherical particals are processed, saving plenty of energy. Therefore, choosing the proper organic fertilizer machine is particularly essential. New type organic fertilizer granulator is the most suitable machine.

- Drying Process:

After granulating, the granules are in need of drying. The moisture of organic fertilizer is reduced to 10%-40%. Rotary drum dring machine is an equipment to reduce the moisture of the particles, which is feasible for organic fertilizer production.

- Cooling Process:

In order to ensure quality, the particles should be cooling after drying with the help of rotary drum cooling machine.

- Screening Process:

There are unqualified organic fertilizers during production. It needs rotary drum fertilizer screening machine to separate the rejected goods from standard substance.

- Packing Process:

Fertilizer packaging machine is used for packing processed fertilizers. We can use packing machine to pack and bag the particles.It can achieve pack products automatically and efficiently.

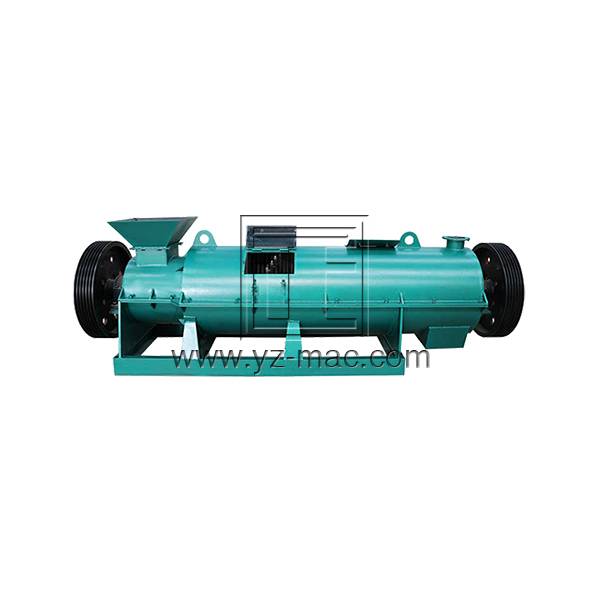

The granulator specification models are 400, 600, 800, 1000, 1200, 1500 and other specifications, which can also be customized according to actual needs.

|

Model |

Granule Size (mm) |

Power (kw) |

Inclination (°) |

Dimensions (L× W ×H) (mm)

|

|

YZZLYJ-400 |

1~5 |

22 |

1.5 |

3500×1000×800 |

|

YZZLYJ -600 |

1~5 |

37 |

1.5 |

4200×1600×1100 |

|

YZZLYJ -800 |

1~5 |

55 |

1.5 |

4200×1800×1300 |

|

YZZLYJ -1000 |

1~5 |

75 |

1.5 |

4600×2200×1600 |

|

YZZLYJ -1200 |

1~5 |

90 |

1.5 |

4700×2300×1600 |

|

YZZLYJ -1500 |

1~5 |

110 |

1.5 |

5400×2700×1900 |

Product detail pictures:

Related Product Guide:

Pig manure organic fertilizer complete equipment

Compound fertilizer production process

4. Screening machine equipment: trommel screening machine. High reputation Disc-Ball Granulator - New Type Organic Fertilizer Granulator – YiZheng , The product will supply to all over the world, such as: panama, Vietnam, Ukraine, The organic fertilizer production line is used to produce organic fertilizers with organic raw materials such as agricultural waste, livestock and poultry manure, sludge, and municipal waste. The entire production line can not only convert different organic wastes into organic fertilizers, but also bring huge environmental and economic benefits. The organic fertilizer production line equipment mainly includes a hopper and feeder, drum granulator, dryer, drum screener, bucket elevator, belt conveyor, packaging machine and other auxiliary equipment.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.