High Quality for Straight Belt Conveyor - Large Angle Vertical Sidewall Belt Conveyor – YiZheng

High Quality for Straight Belt Conveyor - Large Angle Vertical Sidewall Belt Conveyor – YiZheng Detail:

This Large Angle Inclined Belt Conveyor is very well suited for a board range of free-flowing products in the food, agriculture, pharmaceutical, cosmetic, chemical industry, such as snack foods, frozen foods, vegetables, fruits, confectionary, chemicals and other granules.

1) Provide OEM service

2) 20 years of experience

3) We can design and manufacture the conveyor based on your special requirement.

4) Low price sale on spare parts.

1. Low maintenance cost.

2. Large transport capacity, and it can avoid material spilling effetely.

3. The belt can facilitate switching from horizontal to inclined conveying and from inclined to horizontal conveying.

4. It saves a lot space as it allows material conveying at 0-90 degree.

The Large Angle Vertical Sidewall Belt Conveyor can be divided into T, C and TC according to their different sections.

•Type T is suitable for inclination β≤40°;

•Type C is suitable for cases with good material fluidity at an inclination of β>40°;

•TC type is suitable for inclination β > 40°, with large viscosity of materials.

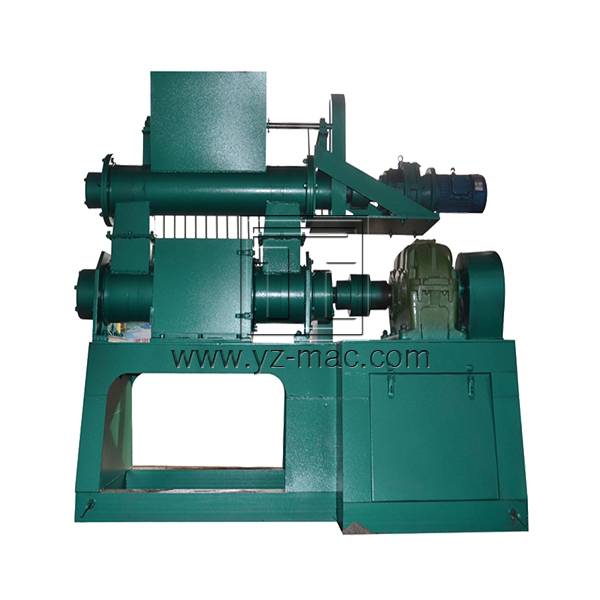

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

The equipment required for NPK compound fertilizer production line usually includes: High Quality for Straight Belt Conveyor - Large Angle Vertical Sidewall Belt Conveyor – YiZheng , The product will supply to all over the world, such as: Brisbane, luzern, Latvia, Fertilizer mixer machine

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!