Graphite granule extrusion pelletizing technology

Graphite granule extrusion pelletizing technology refers to the process and techniques used to produce pellets or granules from graphite materials through extrusion. This technology involves the transformation of graphite powders or mixtures into well-defined and uniformly shaped granules suitable for various applications.

The graphite granule extrusion pelletizing technology typically includes the following steps:

1. Material Preparation: Graphite powders or a mixture of graphite and other additives are prepared according to the desired composition and properties of the final granules. The materials may undergo blending, mixing, and grinding processes to achieve homogeneity.

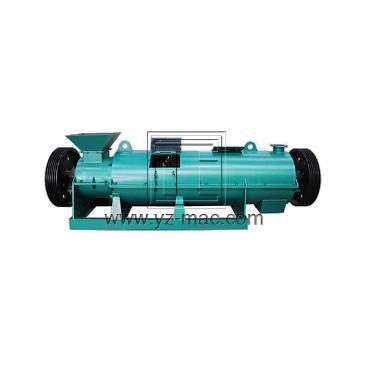

2. Extrusion: The prepared graphite mixture is fed into an extrusion machine or extruder. The extruder consists of a barrel and a screw or a similar mechanism. The material is pushed forward by the rotating screw and subjected to high pressure and shear forces.

3. Die Design and Formation: The extruded graphite material passes through a specially designed die or mold, which imparts the desired shape and size to the granules. The die can have various configurations, such as cylindrical, spherical, or custom shapes, depending on the application requirements.

4. Cutting or Sizing: Once the graphite material is extruded through the die, it is cut into individual granules of the desired length. This can be achieved through a cutting mechanism or by passing the extrudate through a pelletizer or granulator.

5. Drying and Curing: The freshly formed graphite granules may undergo a drying or curing process to remove moisture or solvents and to enhance their strength and stability. This step ensures that the granules are suitable for further processing or application.

The specific parameters and conditions in each step of the graphite granule extrusion pelletizing technology can vary depending on the desired granule properties, equipment used, and intended application. Optimization of the formulation, extrusion parameters, die design, and post-processing steps are crucial to achieving high-quality graphite granules with consistent properties. https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/