Fertilizer mixer machine price

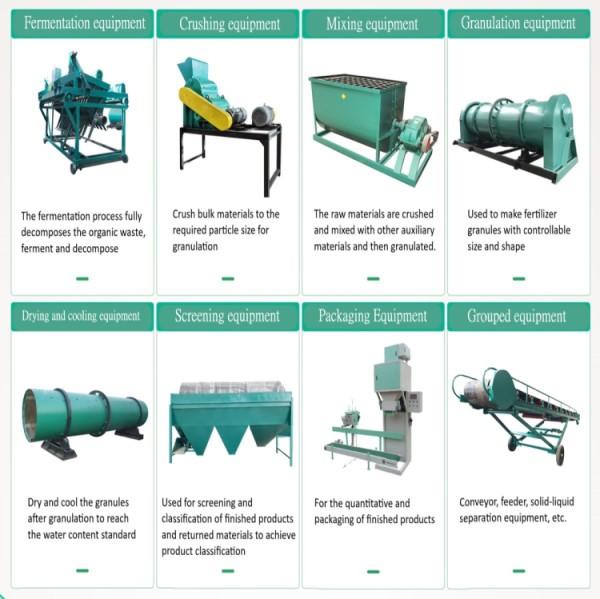

A fertilizer mixer machine efficiently blends various fertilizer ingredients, ensuring a homogeneous mixture that provides balanced nutrient content for optimal plant growth.

Importance of a Fertilizer Mixer Machine:

A fertilizer mixer machine plays a crucial role in the fertilizer production process. It ensures that all fertilizer components, including macronutrients (nitrogen, phosphorus, and potassium) and micronutrients, are thoroughly mixed, creating a uniform blend. This process guarantees consistent nutrient distribution throughout the fertilizer mixture, resulting in better nutrient uptake by plants and maximizing the fertilizer’s effectiveness.

Factors Influencing Fertilizer Mixer Machine Pricing:

Several factors can influence the pricing of a fertilizer mixer machine. These factors include:

Machine Capacity: The mixing capacity of the machine, typically measured in tons per hour or kilograms per batch, affects the price. Higher-capacity machines tend to have higher prices due to their larger size and greater production capabilities.

Material of Construction: The material used to construct the fertilizer mixer machine can impact the price. Machines made from high-quality, durable materials such as stainless steel or corrosion-resistant alloys may be more expensive but offer enhanced longevity and performance.

Mixing Mechanism: Different types of mixing mechanisms, such as paddle mixers, ribbon mixers, or vertical mixers, can influence the price. Each type has its own advantages and mixing efficiency, which can affect the overall cost of the machine.

Automation and Control Systems: Advanced automation features, such as programmable logic controllers (PLCs) or touch screen interfaces, can enhance the precision and ease of operation. However, such advanced features may increase the price of the machine.

Benefits of Investing in an Affordable Fertilizer Mixer Machine:

Enhanced Fertilizer Quality: An efficient fertilizer mixer machine ensures thorough blending of fertilizer ingredients, resulting in a uniform mixture with consistent nutrient distribution. This improves the quality of the fertilizer, leading to improved plant growth and higher crop yields.

Time and Cost Savings: Investing in an affordable yet efficient fertilizer mixer machine can lead to significant time and cost savings in fertilizer production. The machine’s ability to quickly and thoroughly mix ingredients reduces processing time and labor requirements, increasing overall productivity.

Customizable Formulations: A high-quality fertilizer mixer machine allows for precise control over the blending process, enabling the creation of customized fertilizer formulations to meet specific crop and soil requirements. This flexibility enhances the effectiveness of the fertilizer application and promotes optimal plant nutrition.

Long-term Investment: Although the initial cost of a fertilizer mixer machine is an important consideration, it is equally crucial to evaluate the machine’s long-term value. Investing in a reliable, durable machine ensures consistent performance, reduces maintenance costs, and provides long-term benefits for fertilizer production.

A fertilizer mixer machine is a critical component in the production of high-quality fertilizers. It ensures the thorough blending of fertilizer ingredients, resulting in a uniform mixture with balanced nutrient content. When considering the price of a fertilizer mixer machine, factors such as machine capacity, construction materials, mixing mechanism, and automation features should be taken into account. Investing in an affordable yet efficient fertilizer mixer machine offers benefits such as enhanced fertilizer quality, time and cost savings, customizable formulations, and long-term value.