Fertilizer mixer

A fertilizer mixer, also known as a fertilizer blending machine, is a specialized equipment designed to mix different fertilizer materials together, creating a homogeneous blend suitable for optimal plant nutrition. Fertilizer mixing plays a crucial role in ensuring the uniform distribution of essential nutrients in the final fertilizer product.

Benefits of a Fertilizer Mixer:

Homogeneous Nutrient Distribution: A fertilizer mixer ensures the thorough and uniform blending of different fertilizer materials, guaranteeing the even distribution of essential nutrients in the final product. This homogeneity allows for consistent nutrient availability throughout the application, promoting balanced plant growth and maximizing fertilizer effectiveness.

Customized Formulations: Fertilizer mixers offer flexibility in creating customized fertilizer formulations tailored to specific crop requirements. By adjusting the ratios and types of fertilizers used, growers can fine-tune nutrient compositions to meet the specific needs of different plants, soil conditions, and growth stages.

Enhanced Nutrient Utilization: Properly blended fertilizers provide nutrients in a balanced and readily available form, promoting efficient nutrient uptake by plants. The homogeneous nutrient distribution achieved through fertilizer mixing ensures that plants have access to the required nutrients for optimal growth and development.

Cost Efficiency: By blending different fertilizer materials, growers can optimize nutrient content while reducing costs. Fertilizer mixers allow for precise control over nutrient ratios, enabling the use of more economical fertilizer sources without compromising the overall nutrient balance.

Working Principle of a Fertilizer Mixer:

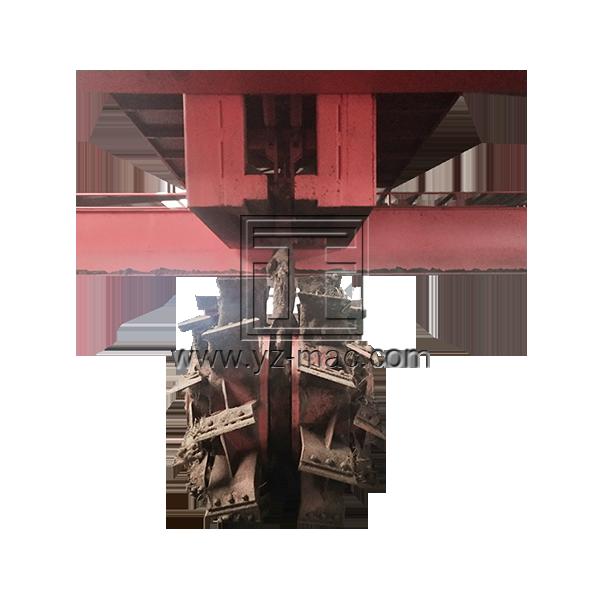

A fertilizer mixer operates by combining different fertilizer materials using mechanical agitation. The machine typically consists of a mixing chamber or drum equipped with blades, paddles, or augers. As the fertilizer materials are fed into the mixer, the rotating blades or paddles create a tumbling motion, thoroughly mixing the components and achieving a homogeneous blend. Some mixers may include additional features, such as adjustable mixing times or speed control, allowing for further customization.

Applications of Fertilizer Mixers:

Agricultural Crop Production: Fertilizer mixers are widely used in agricultural settings to blend fertilizers for various crops. They enable growers to create customized fertilizers that meet specific nutrient requirements, optimizing plant growth and yield. Fertilizer mixers are suitable for both conventional and organic farming practices.

Horticulture and Floriculture: Fertilizer mixers are essential in horticultural and floricultural operations, where specific nutrient compositions are required for the cultivation of flowers, fruits, vegetables, and ornamental plants. By using a fertilizer mixer, growers can produce tailored blends that meet the precise nutritional needs of different plant species and varieties.

Turf Management and Golf Course Maintenance: Fertilizer mixers play a vital role in turf management and golf course maintenance. They enable the preparation of specialized fertilizers to promote healthy and vibrant turf growth. Customized fertilizer blends ensure consistent nutrient delivery, contributing to the aesthetics and playability of the turf.

Nursery and Plant Propagation: Fertilizer mixers are utilized in nurseries and plant propagation facilities to produce nutrient-rich blends for seedlings, young plants, and container-grown crops. Customized fertilizer formulations can be tailored to specific growth stages, ensuring optimal nutrient supply and healthy plant development.

A fertilizer mixer is a valuable tool for enhancing fertilizer blending efficiency and ensuring the uniform distribution of essential nutrients. The benefits of using a fertilizer mixer include homogeneous nutrient distribution, customized formulations, enhanced nutrient utilization, and cost efficiency.